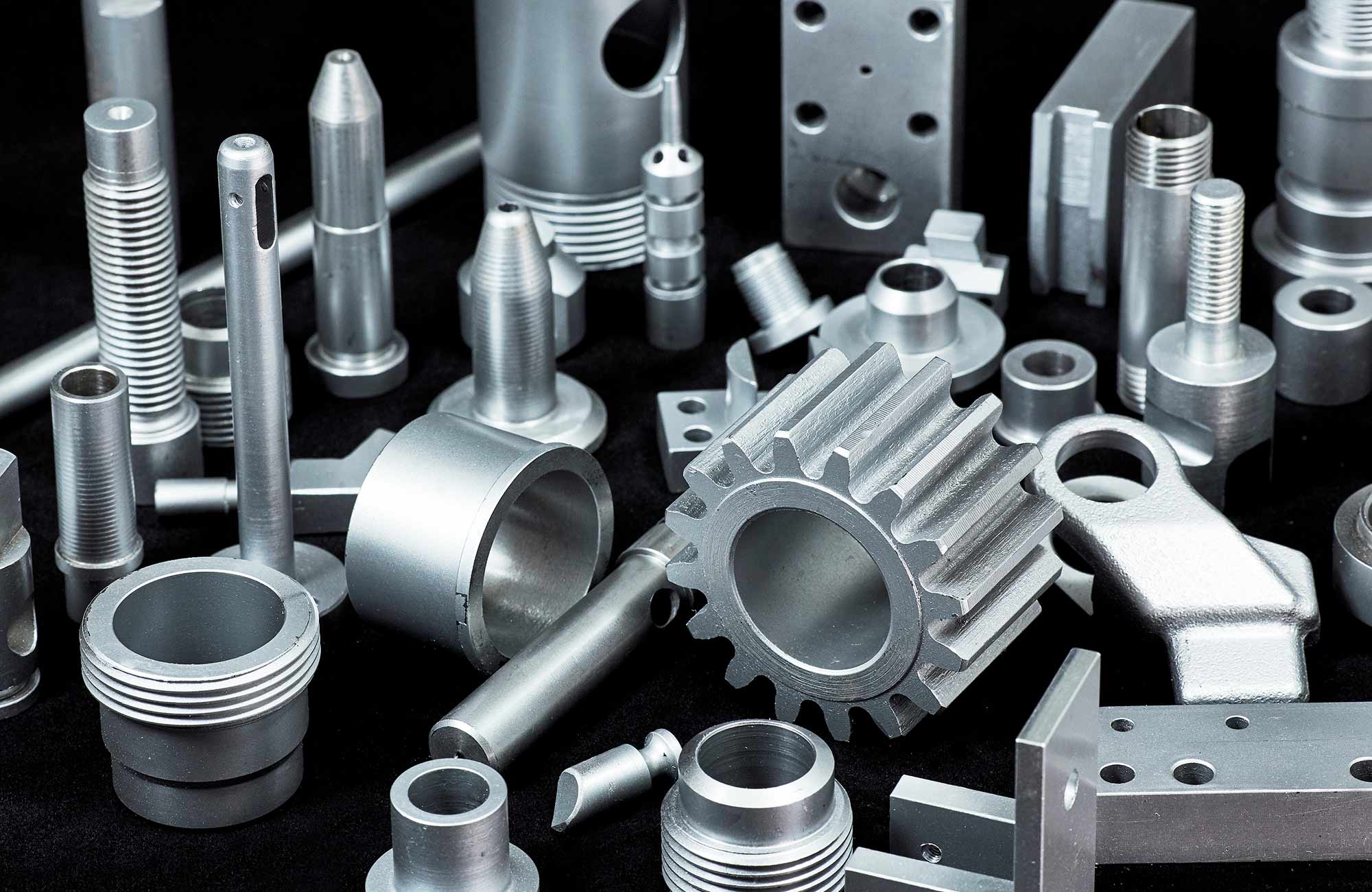

We make metalwork.

We help clients produce premium metal parts by providing industry-specific expertise, cost-effective solutions, a powerful global manufacturing network, and peace of mind with every project.

Our Process

Explore our end-to-end manufacturing process.

Cold Heading

Cold heading has typically been used to create pieces like simple fasteners, though with technology always improving, cold heading can be used to create highly specialized fasteners and specialty pieces.

Custom Fasteners

As important as it is to create quality metal parts, they won’t do any good unless you have something that holds them all together. Such is the job of fasteners.

Metal Stamping

Industries all over the country use metal stamping to create intricate components for machinery.

Metal Fabrication

We provide full-service metal fabrication services, working with you from product research to manufacturing.

Metal Forging

Metal forging is the process of shaping a piece of metal using continuous pressure. Specialties include cold forging, hot forging, and more.

Aluminum Die Casting

Aluminum die casting represents a safe, reliable process by which metal pieces can be cast and molded for a variety of purposes.

Precision CNC Machining

Precision CNC machining works with a variety of materials including metals, woods, acrylics, foams, and thermoplastics.

Screw Machining

Screw machining is the process of rapidly spinning lathes that shave metal down to the desired size.

Our Products

From Prototype to Production

Our team of engineering and manufacturing experts have experience creating products for a wide variety of industries.

Clients & Partners

Quality Management and Integrity

At The Federal Group USA our staff is on the ground for each phase of the Supply Chain Management operation. The Federal Group USA employs engineers who direct machining processes and inspect tooling and equipment to ensure that we are meeting all demands and requirements.

Our ISO 9001 quality management system is under continuous improvement to satisfy our customers’ ever changing requirements. The Federal Group’s Quality Management System is certified ISO 9001 by NSF International. Incorporating world-class excellence, in an ongoing effort to ensure your success.

The Newsroom

Handlebar Assembly Tolerance Study

The following report is an analysis of the hole position tolerance for a handlebar weldment. We have further studied our manufacturing and inspection practices, and have determined that 100% of our parts meet the drawing requirements. We understand that there is an issue fitting the handlebars to the mating “pod” assembly, so you will find our suggestion near the end of this report.

Client Testimonials

Talk To An Expert

Our team is ready to help. Please fill out the form below to get started.

* indicates required fields

Thank you for contacting us. We’ll be in-touch with you shortly.

There was an issue with your submission, please try again later.