Anodizing aluminum parts can be an efficient way of adding enhanced mechanical properties to parts or improving their aesthetics. Read on to learn more about anodizing aluminum, including information about production factory operations and how to anodize aluminum yourself at home.

Table of Contents

Key Takeaways

- Enhanced Durability: Anodizing creates a hard, corrosion-resistant oxide layer without altering part dimensions — ideal for high-wear applications.

- Aesthetic Flexibility: Offers long-lasting metallic or vibrant colors through dyeing, making parts both functional and visually appealing.

- DIY Potential: With basic materials and careful setup, hobbyists can anodize aluminum at home — though safety and precision are essential.

- Process Variations: Type I, II, and III anodizing (plus newer techniques like PEO) provide different thicknesses and performance for diverse industries.

- Industrial Versatility: Used in electronics, architecture, medical, and outdoor equipment for its durability, low maintenance, and clean finish.

- Alternative Comparison: More scratch-resistant and eco-friendly than paint or plating, though limited color range and conductivity can be drawbacks.

Why You Might Want to Anodize Aluminum

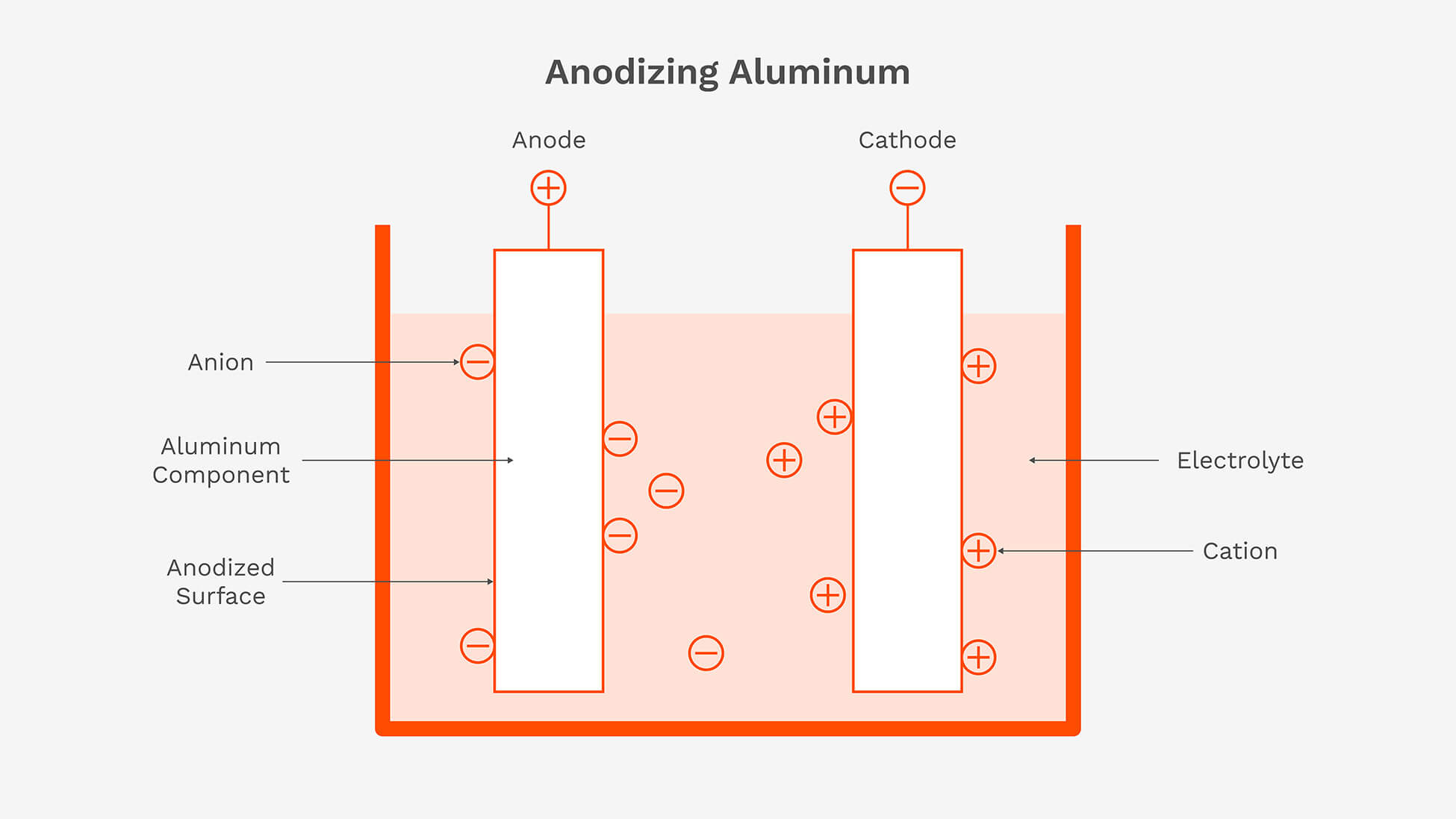

There are several good reasons to consider anodizing your aluminum parts. When anodizing aluminum, a layer of oxide is created, forming a layer on the surface of the part. This layer is so thin that it doesn’t even materially impact the dimensions of precision machined parts. Because the oxide layer is harder than the aluminum, it protects the metal underneath it, making it scratch-resistant and increasing corrosion resistance.

The oxide layer is also rougher than the aluminum surface, making it possible to paint or dye the anodized aluminum. In fact, you can add any color you like to anodized aluminum parts. Coloring is accomplished either by using dyes during the anodizing process or by painting afterward. Dying is preferred, as it creates permanent coloration which means it won’t fade and can’t be scratched off.

Benefits of Anodizing Aluminum Parts

Anodizing aluminum parts provides many benefits, both in terms of aesthetics and the mechanics of the parts themselves.

Durability and Corrosion Resistance

On the mechanical side, the anodizing process makes the surface of the parts extremely durable. The oxide layer is fully integrated with the base layer. It is exceptionally hard and provides superior abrasion and corrosion protection. The thermal insulation properties are also outstanding. This is why aluminum extrusion products are commonly finished by anodizing.

Appearance

On the visual side, the effects of anodized aluminum are quite impressive and the finish is permanent. It is wear-resistant so it will never scratch or fade and will never need a touch-up. Metallic tones and vibrant colors can be achieved, giving anodized parts a sleek appearance.

Eco-friendly

Compared to other metal finishing methods, anodizing is environmentally friendly. The chemicals used can be managed safely and there are no harmful chemicals or volatile compounds released during anodization.

Easy Maintenance

The smooth surface of anodized aluminum resists dirt and grime, making it easy to clean and maintain. In the right application, anodized aluminum will maintain its appearance for years with minimal upkeep. Since it resists staining and corrosion, it is an ideal option for functional and decorative parts in various industries.

Potential Disadvantages

While there are many benefits, there are some cons of anodized aluminum to consider. Depending on the size, shape, and use of the part, anodizing may present challenges. Here are a few factors to consider when determining if anodizing aluminum is the right choice for your project or application.

Limited Color Range

Adding anodized aluminum colors is part art and part science. Anodized color is a chemical transformation where the color is impregnated into the surface of the part. Different anodizing methods will yield various results, and some colors may be difficult to achieve or might not be as vibrant as desired. In manufacturing, it’s essential to partner with a reliable provider to ensure high-quality results.

Thermal Stress Cracking

Anodizing aluminum creates a hard surface on the part, but under certain conditions, this layer can become brittle. In applications where the part undergoes thermal cycling, extreme temperatures, or sudden temperature changes, the outer oxide layer can crack, leading to problems with performance and appearance.

Initial High Cost for DIY Setups

For small parts, home hobbyists can set up an anodizing station without incurring significant costs. However, for larger parts or more advanced setups, the initial setup costs can be relatively high. The cost of specialized equipment, such as tanks, chemicals, and safety gear, can add up quickly.

Environmental Concerns

While anodization is more eco-friendly than many other metal finishing methods, there are environmental considerations. Especially for hobbyists, factors like ventilation and acid waste disposal must be factored into the cost and may make anodizing aluminum at home an expensive endeavor.

Electrical Conductivity

The outside layer of anodized aluminum is an insulating oxide, which significantly impacts the conductivity of the part, making it an unsuitable choice for certain applications. However, there are alternative methods and selective masking that can be used to preserve conductive areas.

Repair Limitations

Since anodization is not a coating, it can’t be repaired by adding another finish. Repairing a damaged part may require that it be completely stripped and re-anodized, which can be costly and time-consuming.

Materials Needed to Anodize Aluminum

The materials you’ll need to anodize are pretty basic and not too expensive. If you think you’ll be doing this somewhat regularly, it makes sense to set up a home anodizing station.

Here’s what you’ll need:

- Sulfuric acid

- Distilled water

- Several tanks (containers) to hold the liquids

- A cathode

- Aluminum wire (titanium will also work)

- Degreaser

- Lye

- Acid neutralizer

- A power source

- Dye (if you want a colored part)

You will also need a well-ventilated area to set up your anodizing station, as well as personal safety gear, including eye protection, gloves, and a respirator.

In addition to the necessary materials above, you may also want to purchase some optional items to make your work easier. These include the following:

- An agitator for the acid bath

- Scotch-Brite pads for cleaning parts before anodizing

- Ping pong balls, which are put in the tank to prevent acid mist

- Cheap tea kettle to heat the dye

- Fish tank heater to regulate tank temperature

- Cooking thermometer for checking temperatures

How to Anodize Aluminum at Home

Below are the basic step-by-step instructions to follow for the at-home hobbyist to anodize aluminum parts yourself. Please keep in mind that it does take time to master the process, and your materials may require some tweaks.

When starting, it’s critical to pay close attention to the voltage and the temperature during anodizing. You can find all sorts of online calculators, but a home setup starting at 16 volts should get you pretty close. Continue to monitor the tank temperature as the process goes along as it can increase during anodization.

- Surface prep– Use the Scotch-Brite pad to clean the surface of the part and remove any machining marks.

- Safety first– Put on your safety equipment, including gloves, safety glasses, and a respirator.

- Clean– Use a degreaser to clean the part well, then rinse with distilled water.

- Etch– Make a lye bath using approximately 4 tablespoons of lye to 1 gallon of water. Dip the parts in the lye bath for about 3 to 5 minutes to etch them, then remove and rinse with distilled water.

- Test cleanliness– Check for cleanliness by pouring water on the piece. If clean, the water should runoff. If the water beads on the surface, the part is not clean enough for anodizing.

- Rack the part– Secure the part to the aluminum (or titanium) wire. Ensure the connection is good. Note that the wire contact point won’t anodize.

- Prepare bath– Mix one part sulfuric acid with three parts distilled water. Anodizing is most successful when the bath temperature is 70 degrees Fahrenheit. Anything above 75°F or below 65°F won’t yield good results.

- Set up the tank– Add the cathode and agitator, ensuring they don’t touch the parts suspended in the tank. Add the heater, thermometer, and enough ping-pong balls to cover the surface. Double-check to make sure the temperature is 70 degrees before proceeding.

- Connect power– Connect the positive terminal to the wire attached to the part and the negative wire to the cathode. Set the power supply to 16 volts, and monitor closely. The amperage is set based on the total surface area being anodized. For a good, hard surface, use 0.03 amps per square inch, and for a softer surface that will take dye better, use 0.02 amps per square inch.

- Prepare dyes– While the anodizing process is going on, heat your dyes. For most colors, 140°F works best, while others work better at cooler temperatures. You’ll have to experiment with your brands and colors.

- Post-anodizing rinse– Prepare one tank of distilled water and another with your acid neutralizer. Turn off the power and remove your parts from the anodizing tank. Dip first in the distilled water for 10-15 seconds, then rinse in the acid neutralizer tank for 5 minutes.

- Dye– Rinse a second time in the distilled water and dunk the parts in the dye. They should immediately begin to take the color, but be sure to leave the parts in the dye for 10-15 minutes, depending on how deep you want the color to be.

- Seal– After finishing with the dye, boil the parts for 15 minutes. Boiling hardens and seals the dye.

Which Types of Aluminum Anodizing Exist?

There are many anodizing methods to choose from, each producing different results to meet various needs. The three most common types of aluminium anodizing are chromic acid anodizing, sulfuric acid anodizing, and hardcoat anodizing.

Type I- Chromic Acid Anodizing

Chromic acid anodizing (Type I) uses chromic acid to create a thin oxide coating on aluminum parts, usually about 20-80 microinches thick, making it ideal for manufacturing components with tight tolerances. When properly sealed, Type I anodizing offers moderate durability and has excellent corrosion resistance. This flexible coating is able to withstand stress and flexing, and is often used in high-precision and critical industrial components.

Type II- Sulfuric Acid Anodizing

In sulfuric acid anodizing (Type II), sulfuric acid is used to produce a thicker oxide layer, usually between 100 and 1,000 microinches thick. Sulfuric acid anodizing allows for a wide range of anodized aluminum colors. Because it is both wear and corrosion resistant, this durable method is popular for applications where protection and aesthetic appeal are essential. It’s the primary method used in a variety of industries, including architecture, construction, and consumer product manufacturing.

Type III- Hard Anodizing

Like Type II, hard anodizing uses sulfuric acid to oxidize the outer layer. In Type III, lower temperatures and increased voltage result in a much thicker layer, typically exceeding 1,000 microinches. A Type III hard coat is exceptionally durable, but usually isn’t the best choice for components with tight tolerances, since some dimensional changes occur during anodization. Hard coat aluminum anodizing is common for parts exposed to extreme conditions, such as industrial equipment and heavy machinery.

Innovative Techniques in Anodizing

Various new techniques in anodizing aluminum are being used to make parts more durable and attractive. Here are some of the most innovative techniques being used to anodize aluminum and other metals.

Plasma Electrolytic Oxidation

Plasma electrolytic oxidation (PEO) is a high voltage process that produces ceramic-like coatings with exceptional wear resistance and thermal stability. PEO improves the wear resistance of aluminum components, even under extreme temperatures. These stronger and more durable coatings are ideal for industrial applications like heavy equipment and other extreme environments.

Laser-Assisted Anodizing

With laser-assisted anodizing, lasers are used to etch designs and patterns onto anodized surfaces. These aesthetic and functional enhancements are used to create custom designs and add logos or other artwork while still maintaining the protective benefits of anodizing. This innovation is popular for personalizing products and adding branding to consumer goods.

Interference Coloring

With interference coloring, the oxide thickness is controlled to create beautiful colors that change depending on the angle. Unlike other anodizing coloring methods, this innovative technique doesn’t use dyes or chemicals. The result is a stunning, iridescent finish that’s often used in everything from high-end products like jewelry and electronics to architectural elements and decorative trims.

Nanotechnology in Anodizing

Nanotechnology in anodizing uses an electrochemical process to change the structure of metals at a microscopic level, improving the uniformity, strength, and functionality of anodized coatings. This technique allows for better color control and improved corrosion resistance, and it’s an ideal solution for components with extremely tight tolerances. Nanotechnology in anodizing is being used in industries like the medical field and electronics, where superior performance is essential.

Industry Applications

Anodizing aluminum plays an essential role in improving the performance of components in a wide range of industries. From consumer goods to industrial equipment, here are some of the benefits that aluminum anodizing provides to enhance the functionality and appearance of parts used in various sectors.

Electronics and Consumer Goods

Anodizing enhances the appearance and durability of electronics like smartphones, laptops, and cameras. It provides a vibrant, scratch-resistant surface that not only looks great but also protects consumer goods like these from everyday wear and tear.

Architectural Applications

Anodizing is used to manufacture components used in architectural applications. Anodized aluminum is used in everything from curtain walls and window frames to roofing and trim. Since it provides exceptional corrosion resistance and aesthetic appeal, anodized aluminum is an ideal choice for these applications. Another benefit is that it is low maintenance, requiring minimal upkeep to maintain its appearance over time.

Medical Equipment

Because anodized aluminum is easy to clean and sanitize, it’s often used to manufacture medical equipment. Known for its superior biocompatibility, meaning it is compatible with living tissues without causing adverse effects, anodized aluminum is often used in surgical and diagnostic equipment.

Industrial Equipment

Anodized aluminum is frequently used in heavy-duty industrial applications because of its ability to resist wear, corrosion, and other environmental damage. The anodized layer provides a hard, protective surface, making it ideal for components like machinery parts, electrical enclosures, and heat sinks.

Sporting and Outdoor Equipment

Anodized layers are commonly applied to sporting and outdoor equipment such as bicycles, boats, and camping gear. Not only does anodizing aluminum make it more visually appealing, but it also helps equipment resist scratches and retain colors in harsh conditions.

How Does it Compare to Other Alternatives?

Rather than simply creating a protective coating, anodized aluminum is a seamless integration that forms a protective oxide layer. Compared to other metal finishing alternatives like powder coating, electroplating, and painting, anodizing aluminum stands out for its durability and corrosion resistance. This type of coating lasts longer and is more scratch-resistant, although it does have a few minor drawbacks.

While painting aluminum is a cost-effective coating method that offers a wider range of colors, anodizing is more durable and less prone to chipping. Similarly, electroplating provides a metallic finish that’s highly conductive, but it lacks the wear resistance that anodizing provides.

There are a few cons of anodized aluminum. Overall, it is ideal for applications like electronics, consumer goods, and architectural elements. Products like mailboxes, vent covers, and laptops are all made with anodized aluminum, and although other alternatives might be better if your project requires conductivity or a broader color palette, anodizing is an excellent choice where low maintenance and durability are primary concerns.

Robert Levy

Manufacturing Business Leader

Owner of The Federal Group for 44 years, Robert is a serial entrepreneur and built his manufacturing business from scratch at the age of 26. He is an expert on all things forging, casting, and machining. On the weekends, he enjoys golfing, playing guitar, and spending time with family.

Up Next