Cornering the Market: Gravity-Cast End Caps for Lang Trailers

As a trusted gravity casting company, The Federal Group helped Lang Specialty Trailers upgrade a basic aluminum corner cover into a high-end, branded component that enhanced both performance and aesthetics. This case study explores how strategic design, material selection, and careful finish optimization turned a small detail into a signature element of Lang’s premium trailers.

A Small Part with a Big Brand Presence

When Lang Specialty Trailers—a leader in custom-built luxury restroom and hospitality trailers—set out to elevate their flagship line, they wanted every detail to reflect the same craftsmanship as what was inside. That meant they weren’t cutting corners—they were embellishing them.

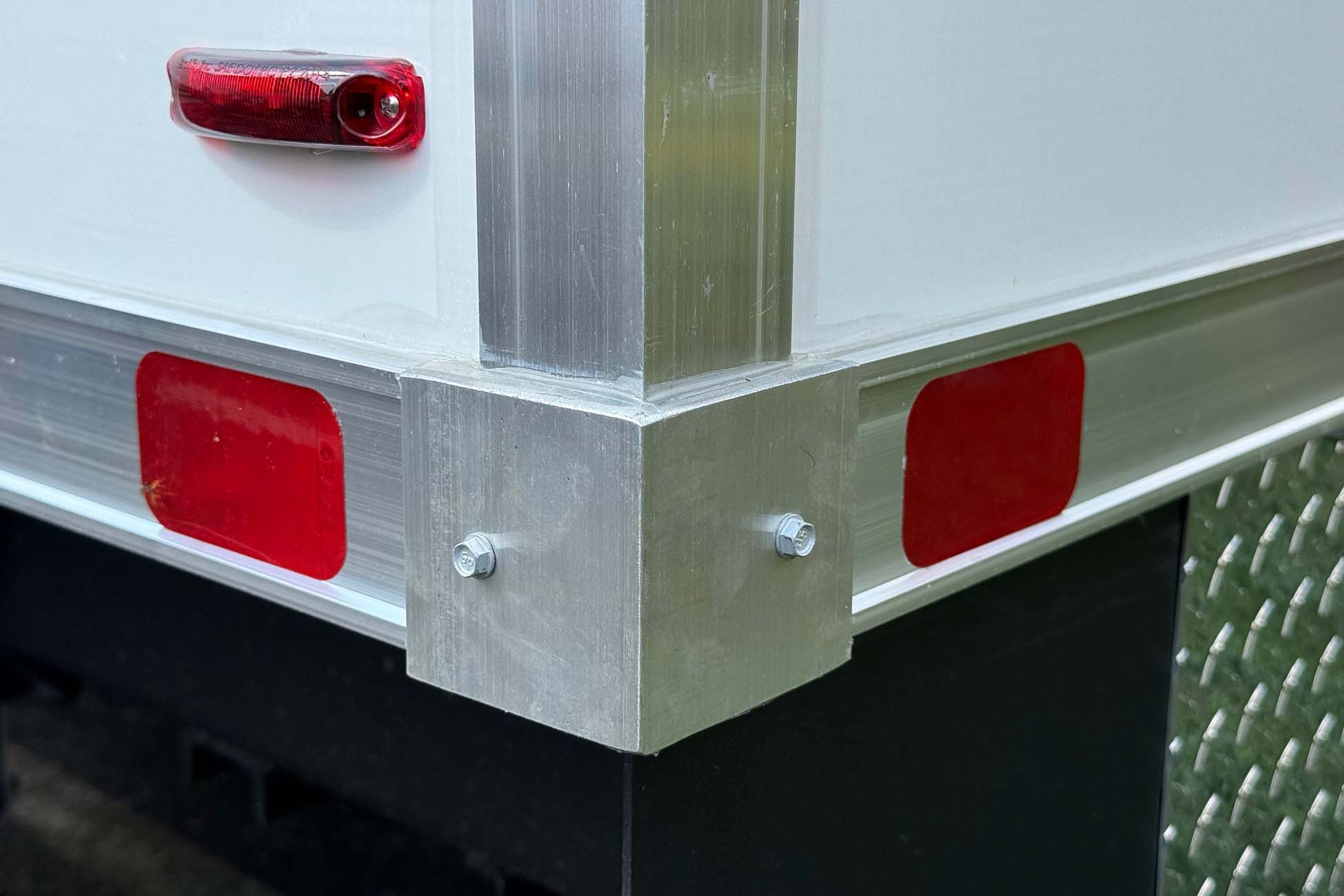

The Federal Group was brought in to reimagine a simple extruded aluminum joint cover into a branded, gravity-cast metal end cap—complete with the Lang logo cast directly into the mold. The new cap needed to look premium, perform reliably, and match the aesthetic of Lang’s high-end trailers used at weddings, events, and commercial sites across the country.

What began as a straightforward upgrade quickly evolved into a precision exercise in cost, surface finish, and color matching. After more than five months of iterative testing and careful material selection, the project became a masterclass in partnership and persistence, proving that when branding meets parts manufacturing, every shade and sheen matters.

Challenge: Putting a Cap on Costs—and Colors

Co-founders and brothers Adam and Steve Ghrist wanted a premium look that matched the elegance of their top-line trailers, without ballooning costs or compromising durability. The new corner caps needed to look flawless right out of the box, hold up to the elements, and align perfectly with the trailer’s clean, cohesive branding.

And while the functional requirements were well-defined, it was the aesthetic expectations that proved the true test

Function Meets Form

What started as a visual upgrade quickly revealed a balancing act between beauty and practicality.

- The caps needed to integrate seamlessly with existing extrusions, maintaining a snug, consistent fit across thousands of units.

- The finish had to match the signature Lang gray, a color that shifts subtly under different lighting conditions and finishes.

- And the production process needed to stay efficient and scalable, ensuring every piece delivered a luxury finish without a luxury price tag.

Finding a solution that checked all three boxes would take precision, persistence, and plenty of patience—the very qualities that define both the Lang and TFG teams.

The Color Conundrum

If there was ever a test of those above qualities, it was the color-matching phase.

Over five months, The Federal Group team tested multiple materials, multiple paint colors, and several finish variations—from matte to high-gloss metallic—before landing on the final combination: a refined metallic gray that elevated the part from utilitarian to unmistakably Lang.

Each round brought the team closer to the perfect hue—but also underscored the importance of collaboration. Working hand in hand with Lang’s founders, TFG refined surface prep, coating processes, and even how the color interacted with natural light.

Because when you’re building a premium brand, close enough isn’t good enough.

Analysis: Making Every Choice Count

In the end, the project wasn’t defined by a single breakthrough, but by a series of intentional choices—each one made to reflect the same craftsmanship and attention to detail that define Lang’s luxury trailers.

Prototyping That Set the Stage—and the Scene.

Once the overall geometry and casting method were approved, prototyping moved swiftly.

The Federal Group’s engineering team transitioned Lang’s original extruded aluminum corner cover to a gravity-cast design, allowing the Lang logo to be molded directly into the cap.

The shift not only elevated the visual impact but also improved consistency, removing the need for secondary machining or engraving. Early trials confirmed proper mold flow, surface uniformity, and fit alignment with the trailer’s extrusions—proof that the fundamentals were solid from the start.

Which metal is best for your next project: aluminum or steel?

The Color of Patience

While the molds performed beautifully, the finish proved far more finicky. The final color—Lang’s signature gray—had to appear as a seamless addition to their elevated trailer line.

Over the course of several months, TFG’s team conducted an extensive series of paint, coating, and finish trials to match tone, texture, and reflectivity of the other trailer materials. Every variable mattered: surface prep, primer thickness, cure time, and even humidity during application.

Through methodical testing and collaboration with Lang’s team, the perfect formulation was achieved—a subtle metallic gray that complemented the trailers’ sleek aesthetic and held up against weather, wear, and road exposure.

Results: Celebrating the Finish Line

In the end, the new gravity-cast corner caps didn’t just elevate Lang’s trailers—they helped reinforce the brand itself.

The final design

- Delivered a premium finish at a practical price, balancing high-end appearance with manufacturing efficiency.

- Achieved color consistency across every unit, ensuring the “Lang gray” maintained its sophistication in any light.

- Improved durability and fit, thanks to tighter tolerances and a more resilient coating system.

Each success built upon the next—proof that precision, persistence, and a little bit of polish can go a long way.

Turning Corners into Calling Cards

For Lang, these corner caps became more than a functional upgrade—they became a design signature. Their subtle gleam and integrated branding turned an overlooked detail into a point of pride.

And for The Federal Group, it was a reminder that great partnerships, like great finishes, take time, patience, and a shared obsession with getting it just right.