In the realm of precision engineering and manufacturing, few materials hold the versatile appeal and reliability of aluminum. Its unique properties made it a prime choice for crafting this part via die casting and CNC machining.

Crafting a Cast

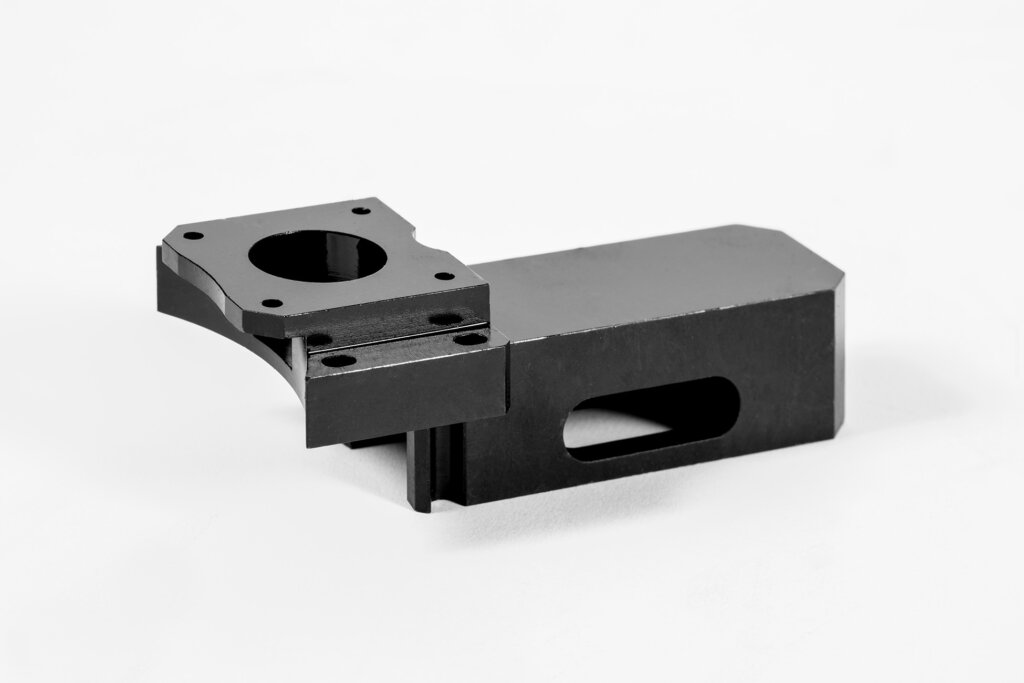

The beginning of this manufacturing journey began as molten aluminum injected into a precision crafted die, meticulously shaped to exact specifications. Through the aluminum die casting process, we harnessed the resilience and versatility of aluminum, creating parts that withstand the test of time while exemplifying unmatched quality and innovation.

Cut and Run

Born from the fiery crucible of the die-casting process, this component emerged with the sturdy resilience inherent to aluminum. Yet, it was the fine touch of CNC machining that elevated its form to unparalleled tolerances.

The CNC machine sculpted and honed every contour, ensuring that each facet of this part adhered flawlessly to its intended design. Considering this part would fit into a larger assembly, every tolerance had to be perfect.

The Finishing Touches

After the machining process, a black oxide coating was applied that transformed its surface, lending a sleek sheen while fortifying its resistance to corrosion and wear. The journey from raw aluminum material to a finished CNC machined part is a perfect example of precision manufacturing.

Contact The Federal Group today for a free quote on your next die casting or CNC machining project.

Robert Levy

Manufacturing Business Leader

Owner of The Federal Group for 44 years, Robert is a serial entrepreneur and built his manufacturing business from scratch at the age of 26. He is an expert on all things forging, casting, and machining. On the weekends, he enjoys golfing, playing guitar, and spending time with family.

Up Next