Choosing the wrong casting method isn’t just a minor engineering oversight. It often leads to ballooning tooling costs, extended production delays, or critical part failures in the field. You might save money on the initial mold, but if that “cheap” sand casting requires three hours of secondary machining to hold tolerance, you haven’t really saved much.

At The Federal Group USA (TFG USA), we have spent over 40 years manufacturing parts to exacting standards for a variety of industries, so we have seen our fair share of engineers caught between strict built-to-print specifications and tight budget constraints.

This guide moves beyond textbook definitions. We will look at the hard data, including costs, tolerances, and surface finishes, that you need to optimize your specific project. Whether you are designing an industrial pump housing or a heavy-duty manifold, the goal is the same: reliable production at the right cost.

Table of Contents

Key Takeaways

- Investment casting is the choice for high precision, complex geometries, and smooth surface finishes (Ra 63-125), but it comes with higher initial tooling costs.

- Sand casting is the heavy lifter ideal for large parts, lower volumes, and projects where looser tolerances are acceptable, offering significantly lower tooling costs.

- Total cost of ownership (TCO) matters more than unit price. Sand casting often requires expensive secondary machining, which can make investment casting cheaper in the long run.

- Volume dictates strategy. High-volume production often justifies the higher upfront cost of investment casting molds to save on per-unit labor.

The Core Difference: Precision vs. Volume

If you need a quick answer to “What is the difference between investment casting and sand casting?”, here is the bottom line.

- Investment casting (lost wax) is the king of precision. It creates near-net-shape parts with complex geometries that require less machining. It’s the go-to for intricate components where surface finish is critical.

- Sand casting is the heavy lifter. It uses a reusable pattern to create a disposable sand mold. It’s unbeatable for large, heavy parts or lower production volumes where surface roughness is less of a concern.

Use this comparison data to orient your decision immediately:

Feature | Investment Casting | Sand Casting |

Cost Strategy | High tooling cost, lower machining cost | Low tooling cost, higher machining cost |

Surface Finish | Smooth (Ra 63-125) | Rough / Grainy (Ra 250-500) |

Precision | High (+/- .005 inch) | Low (+/- .030 inch) |

Speed to Market | Slower (Complex tooling creation) | Faster (Simple pattern making) |

Volume Sweet Spot | Mid-to-High Volume | Low-to-Mid Volume |

Typical Part Size | Ounces to 100 lbs | Pounds to Tons |

How Both Methods Work in Practice

To understand why costs and lead times differ so wildly, you have to look at the workflow. The complexity of the lost wax process is exactly why it yields better precision, but that complexity adds labor.

The Investment Process (Lost Wax)

This method is all about the ceramic shell. We start by injecting wax into a metal mold to create a replica of your part. These wax patterns are then attached to a “tree” and dipped repeatedly in a ceramic slurry. Once that shell hardens, we melt the wax out (hence the name “lost wax”) and pour molten metal into the hollow void. This results in a seamless part with no parting lines in the critical areas.

The Sand Process (Mold-Based)

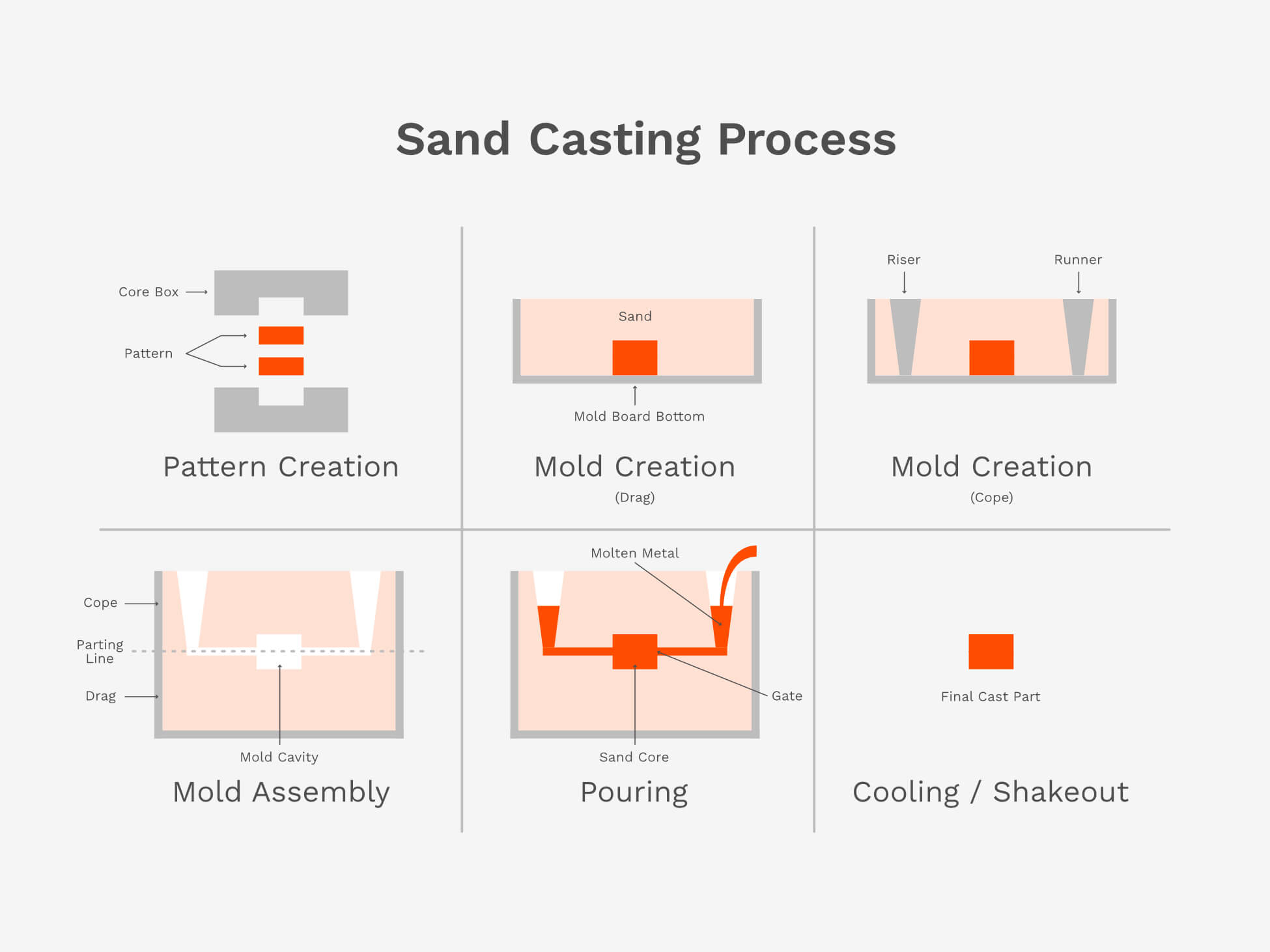

This is a more rugged approach. We build a master pattern (usually wood or metal) that looks like your part. We pack “green sand” or resin-bonded sand around this pattern. The mold is split in half to remove the pattern, then put back together. Molten metal is poured into the cavity. Once it cools, we literally shake the sand off the part. The grainy texture of the sand is transferred directly to the metal surface, which defines the finish.

5 Key Factors That Could Decide Your Choice

Naturally, you can’t make this decision based on generalities alone as we need to look at the specific engineering constraints of your part as well. Here is how the two methods stack up on the factors that actually drive production success.

Surface Finish and Aesthetics

This is often the first thing a customer notices. Because sand casting relies on packing grains of sand against a pattern, the resulting metal surface retains that granular texture. It’s rough to the touch, typically measuring between Ra 250 and 500. If your part is hidden inside an engine block, this might not matter.

But if you are designing an exposed component, sand casting forces you to spend time and money on grinding and polishing. Investment casting uses a ceramic shell formed around a smooth wax pattern, so it replicates that smooth surface more accurately. You get an as-cast finish of Ra 63-125, which is often good enough to go straight to assembly or plating.

Dimensional Tolerances and Precision

Precision is where investment casting separates itself from the pack. We call it a “near-net shape” process because the part comes out of the mold almost exactly as designed. You can hold tight linear tolerances without needing a CNC machine to clean it up.

Sand casting is less predictable. The split mold line, the shifting of the sand, and the thermal expansion of the large volume of metal mean you need to design with wider tolerance bands.

Dimension (Inches) | Investment Casting Tolerance | Sand Casting Tolerance |

0 - 1" | +/- 0.013" | +/- 0.071" |

1 - 3" | +/- 0.015" | +/- 0.087" |

3 - 6" | +/- 0.017" | +/- 0.100" |

6 - 9" | +/- 0.020" | +/- 0.110" |

Tooling Costs vs. Unit Price

This is the most common point of friction we see in procurement. An engineering manager looks at a quote for investment casting tooling, often an aluminum wax mold costing $6,000 to $15,000, and balks. They compare it to a sand casting pattern that might only cost $2,000.

But you have to look at the unit price. Sand castings are heavier and require hours of machining to remove draft angles and bring features into tolerance. That machining time costs money every single time you make a part. Investment casting has a higher entry fee, but the unit price drops drastically because you skip those secondary operations.

Production Volume and Scalability

Sand casting is the king of low volume. If you only need 50 prototypes or large replacement parts, it makes no sense to cut a $10,000 die. You can make a wood pattern in a few days and be casting next week.

But scaling sand casting is a logistical headache. Managing thousands of heavy sand molds takes up massive floor space and labor. Investment casting scales elegantly. We can mount dozens of wax patterns onto a single tree, allowing us to cast hundreds of parts in a single pour. When volume hits the thousands, investment casting becomes the clear winner for efficiency.

Material Versatility and Design Freedom

Both processes handle a wide range of ferrous and non-ferrous alloys, including stainless steel, aluminum, and carbon steel. But design freedom differs.

Sand molds require “draft angles,” which are a slight taper on vertical walls so the pattern can be removed from the sand without breaking the mold. You also cannot easily cast undercuts or thin walls because the sand will crumble. Investment casting uses a ceramic shell that is broken away, not reused. That means we can cast complex undercuts, thin walls, and intricate internal passages that would be impossible in sand.

The Hidden Costs of Making the Wrong Choice

The biggest mistake we see isn’t choosing a “bad” process, but choosing the wrong process for the lifecycle of the part. This drives up the total cost of ownership (TCO) in ways that aren’t obvious on the initial spreadsheet.

You might choose sand casting to save $10,000 on tooling. But if that choice forces you to add a 20-minute CNC operation to every unit to fix the surface finish, you burn through those savings in the first production run. Conversely, forcing a simple, heavy bracket into investment casting is a waste of engineering resources.

This is where TFG USA operates as your Design for Manufacturing partner. Because we handle both investment and sand casting, we don’t have a bias. We don’t need to sell you one method over the other.

Our engineering team reviews your CAD files before a single tool is cut. We look for the “gotchas” – the tight tolerances that will fail in sand, or the heavy sections that will cause porosity in investment. We can even help you execute a hybrid strategy: using sand casting for rapid prototyping to validate the design, then transitioning to investment casting for mass production once the design is locked.

Making the Call: When to Choose Which Casting Method

To simplify the engineering review, use this decision logic. It cuts through the noise and focuses on the constraints that matter.

Choose sand casting if:

- You are in the prototyping phase or need low volumes (<500 units).

- The part is physically large (over 100 lbs) or bulky.

- Surface finish and tight tolerances are not critical.

- You need parts immediately and cannot wait for metal tooling.

Choose investment casting if:

- You are moving into mass production.

- The design features thin walls, undercuts, or complex geometry.

- You need a “near-net shape” to reduce machining costs.

- Aesthetics and surface finish are critical to the end-user.

Making the Right Manufacturing Decision

There is no universally “better” casting method. There is only the method that aligns with your budget, timeline, and technical requirements.

Feature | Investment Casting | Sand Casting |

Pros | High Precision (+/- 0.010") Excellent Surface Finish Minimal Machining Complex Geometries | Low Tooling Costs Fast Prototyping Handles Huge Parts Simple Process |

Cons | High Tooling Cost Longer Lead Time Size Limitations | Rough Surface Finish Lower Precision High Machining Costs |

The key to success is validating your choice early. Don’t wait until the molds are made to discover a tolerance issue. Reach out to The Federal Group USA for a DFM review. Let our engineers analyze your prints and provide a data-backed recommendation that secures your supply chain and protects your margins.

FAQs

What are the main disadvantages of investment casting?

The primary disadvantages are the high upfront cost of the metal tooling (mold) and the longer lead time required to manufacture that tooling. It’s also limited by size. You generally can’t investment-cast parts weighing hundreds of pounds, which is easy for sand casting.

Can you switch from sand casting to investment casting later on?

Yes, and this is a common strategy. However, it usually requires part design modifications. You can often remove draft angles and reduce wall thickness when moving to investment casting. It’s best to plan for this transition during the initial design phase to avoid total redesigns.

Which casting method is faster?

Sand casting is generally faster for the first article. Making a wood or plastic pattern can take days, whereas machining a wax injection mold for investment casting can take weeks. But for high-volume production runs, investment casting is faster per unit.

Is investment casting stronger than sand casting?

Generally, yes. Investment casting allows for better control over the metallurgical structure and reduces defects like porosity. However, the ultimate strength depends heavily on the specific alloy used and the heat treatment process applied after casting.

Holly Cacilhas

Quality Manager

Holly has over 18 years of experience in quality and has worked with brands such as Tesla, BMW, and Chrysler. She has led, trained, and managed teams between 25 and 400 people. Holly enjoys camping, boating, and spending time with her family.

Up Next