Custom Sand Casting Services

The Federal Group USA is a premier global sand casting manufacturer that offers a wide range of high-quality metal casting services. Sand casting remains one of the most cost-effective, widely used, and efficient casting solutions, helping to reduce lead time and costs.

Request a QuoteUnmatched Experience

Manufacturing complex custom castings since 1980

Diverse Materials

Stainless steel, alloy steel, iron, aluminum, and more

Custom Applications

High and medium volume production solutions

High-Quality Standards

Quality management systems that are certified to ISO/QS/TS

Industries We Serve

Our products are made with durability and precision in mind. As a leading sand casting company, The Federal Group USA serves a wide range of industries, relying on decades of experience in sand casting. We use advanced technologies to provide the highest quality cast components to the industrial manufacturing, energy, and construction sectors.

Industrial Manufacturing

TFG USA produces custom parts for industrial machinery and plant infrastructure. Our sand casting services are a cost-effective solution for low volume runs, focused on creating reliable components that meet strict performance standards. Using advanced technologies like solidification modeling and 3D printing, we keep your costs low while producing quality precision parts.

Energy Sector

Bringing extensive experience to the manufacture of high performance parts for the energy sector, TFG is a leading sand casting manufacturer for components like turbines, pump housings, and valve bodies. Our quality sand casting services ensure that each part meets the energy industry’s demands for durability, able to withstand the extreme temperatures and high pressures these critical components are exposed to.

Construction and Beyond

From precision cast brackets to custom fittings and heavy duty parts for construction machinery, our custom sand casting solutions are designed to meet the specific needs of the construction industry. We work closely with our clients to deliver quality sand castings that meet the demanding conditions of construction environments.

What Is Sand Casting?

Sand casting is a type of metal casting technique that involves the use of sand to create a mold. Molten metal is poured into the mold to create the final product. This manufacturing process is used to create metal products in a wide range of shapes and sizes.

Is Sand Casting Right for Your Product?

Image above: A clevis manufactured via sand casting.

Sand molded castings are cost-effective but may not be the best manufacturing process for every product or part. Key things to consider are quantity, budget, production timeline, shape, dimensional accuracy, tolerances, and surface finish.

The Advantages of Sand Casting

The main advantages of this casting process include:

- Lower costs for low-volume production runs

- Suitability for fabricating large parts and components

- Ability to use ferrous or non-ferrous metals

- Shorter lead time compared to other processes

One of the most attractive features is that it has the lowest initial setup cost. The process is also easier to modify and reduces the cost of changes to the sand casting mold.

Due to these features, this method of casting is ideal for the fabrication of low- to medium-volume production runs, prototype castings, and the conversion of welded components to castings.

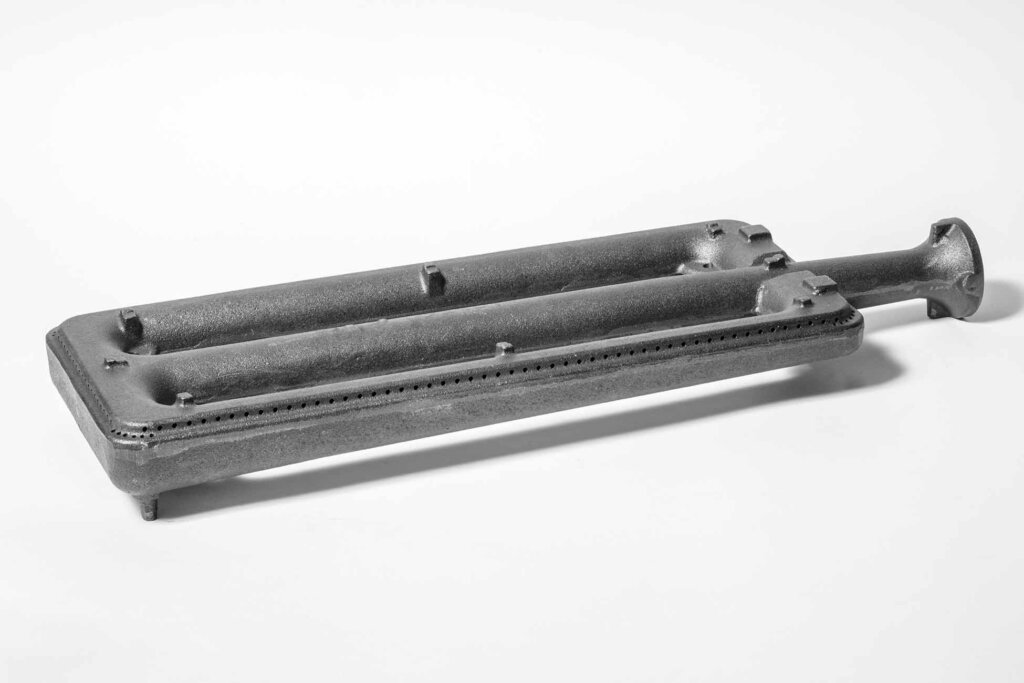

Our Sand Casting Process

Image above: Commercial stove burner manufactured via the sand casting process.

We offer a variety of sand casting methods and materials to suit your project, including:

- Greensand molding

- Resin sand molding

- Air set molding

Along with these processes, we offer a complete metallurgical analysis. With our state-of-the-art foundry, we can prepare metals for analysis to help reduce casting defects and process inefficiencies.

Our solutions also allow for the use of a wide range of materials including stainless steel, alloy steel, iron, aluminum, magnesium, brass, bronze, and copper. Our equipment includes magma solidification software to reduce or eliminate porosity. We also utilize a coreless induction melting furnace to increase productivity.

Our Sand Casting Equipment

- Magma Solidification Software: Using this software results in better pattern making and gating to reduce or eliminate porosity.

- Coreless Induction Melting Furnace With a fast heat-up time, this combines high productivity with maximum alloy flexibility.

- Channel Holding Furnace: The channel holding furnace combines high productivity with the economical operation and provides a continuous supply of ready-to-pour molten metal 24 hours a day.

- Automatic Sand Molding Machine: Made with mechanical automation and used for high volume casting, all molds have the same dimensions, tension, moisture content, and other properties.

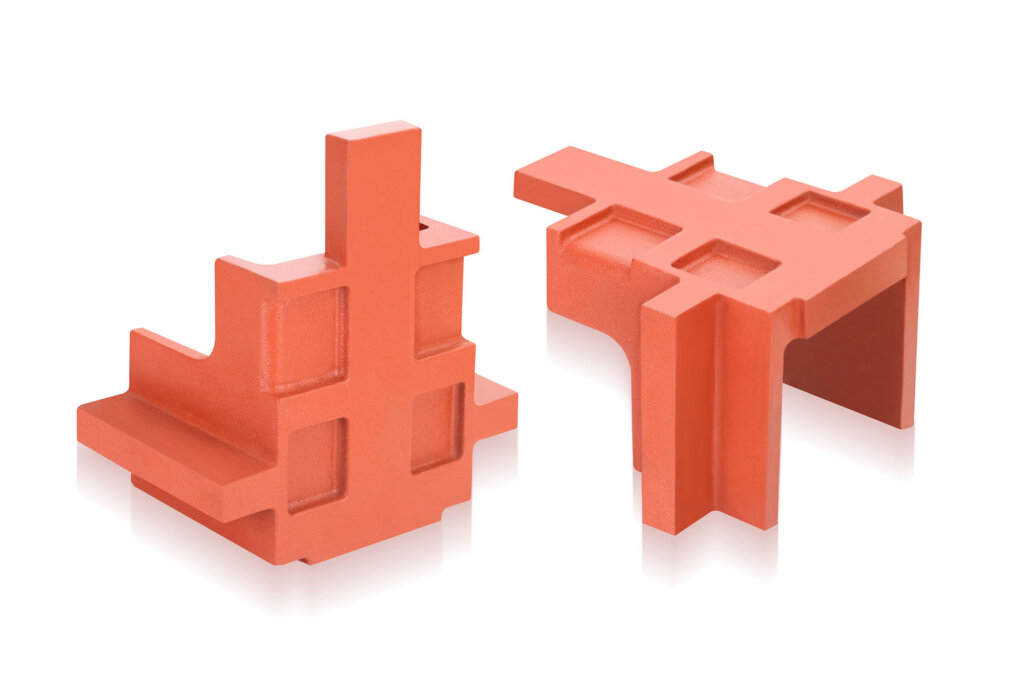

The Federal Group’s Sand Casting Capabilities

Image above: A sand casted and machined product finished with a rust preventing paint. Manufactured by The Federal Group.

Our foundry capabilities have a wide range from 1 lb to 30,000 lbs per piece. Different materials and methods can be used to achieve the ideal result for your casting products:

Green Sand Molding

Castings are made using sand molds formed containing water and organic bonding compounds (typically clay).

Resin Sand Molding / Shell Molding

Castings are made with resin sand, which is a mixture of quartz sand and resin. Also known as a hard mold, the resin sand becomes very hard and solid after mixing and burning.

No-Bake / Air Set Molding

This sand casting process involves the use of chemical binders to bond the molding sand at room temperature. Heating is not necessary for this process.

Complete Metallurgical Analysis

- Our state of the art lab is fully capable of preparing metals for analysis.

- Microscopic and Macroscopic Analyses: Sectioning, mounting, polishing, and micro etching are done to prepare the metal for analysis.

- X-Ray Diffraction Analysis: We are also capable of preserving the specimen: This is a nondestructive technique for characterizing crystalline material or minerals.

- Fully Equipped Sand Testing Lab: Capable of testing all of the characteristics of prepared sand for casting, we have maximum control over processes. This identifies casting defects and process inefficiencies, resulting in superior products at a lower cost of operation.

Our Sand Casting Materials

Various metal material can be used for sand casting depending on the application and desired properties of the final product. We use the following materials in our sand castings:

- Alloy Steel

- Aluminum

- Brass, Bronze & Copper

- Cast Iron

- Grey, Ductile & White Iron

- Magnesium

- Stainless Steel/ Duplex 2205, 2507 & Zeron

Contact Us Today for a Free Sand Casting Quote

If you’re interested in getting a quote for your upcoming sand casting project, contact The Federal Group USA today. We’re happy to talk through our manufacturing process and any other metal casting services you may be interested in.