In the realm of urban design and traffic management, bollards or bollard posts stand as guardians, integral in shaping our cities’ safety and aesthetics. These unassuming posts serve a multitude of purposes, from guiding traffic to providing security and delineating pedestrian spaces. But have you ever wondered about the science and art behind the creation of a bollard?

Table of Contents

What Are Bollards?

A bollard is a sturdy, vertical posts or barrier typically made from materials like stainless steel, concrete, or aluminum. They come in various shapes, sizes, and designs, but their primary function is consistent: to manage and control vehicular or pedestrian traffic.

While we often see them lining sidewalks, streets, or parking lots, they also find extensive use in areas requiring heightened security, like government buildings, airports, and stadiums.

Types of Bollards

Bollards come in diverse types catering to different functions. Tho most common bollard designs are:

- Fixed or permanent bollards are securely anchored into the ground via bolted hardware and remain immobile, providing long-term stability.

- Removable bollards, on the other hand, offer flexibility, allowing temporary access to restricted areas. There are also retractable or collapsible bollards, which can be lowered or raised as needed, offering a balance between accessibility and security.

- Parking bollards are specific types of bollards used in parking lots or parking structures to manage and control vehicle traffic in high traffic areas. These can be fixed or removable bollards. Some might even allow for bollard covers which is great for reducing maintenance costs.

- Security bollards or safety bollards are robust, strategically placed barriers designed to prevent unauthorized vehicle access and protect vulnerable areas from potential threats or vehicular attacks.

- Custom bollards offer tailored solutions to specific needs or settings, providing advantages that off-the-shelf options might not fully address. There are several reasons someone might opt for custom-manufactured bollards including unique design requirements, site constraints, or specialized functionality.

Bollard Manufacturing Process

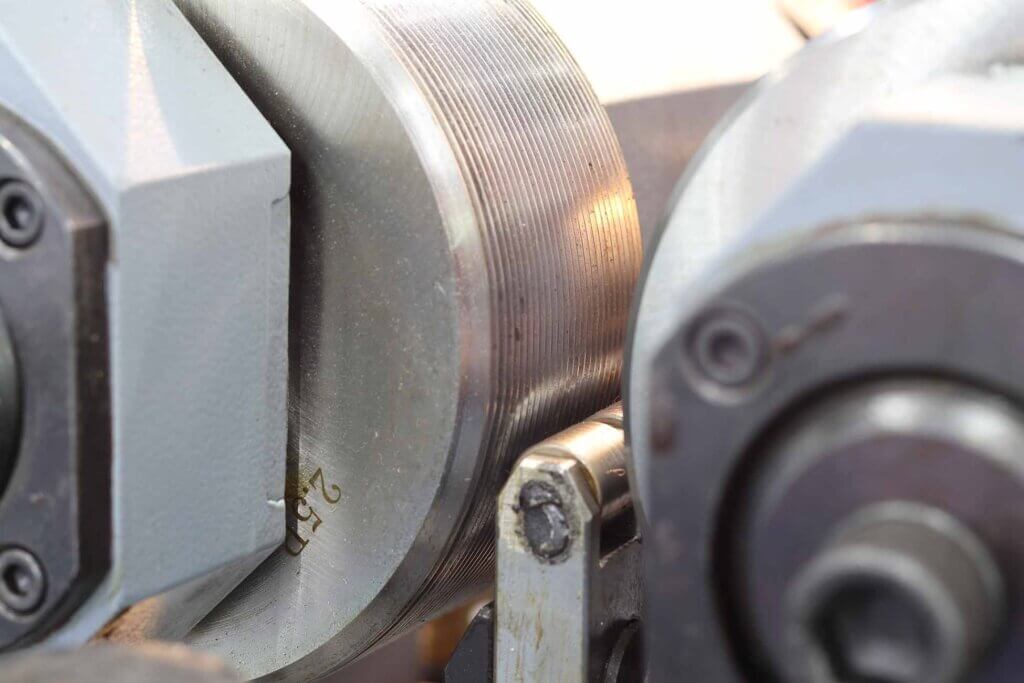

The production of bollards involves a series of precise steps and the use of various materials, depending on the intended purpose and durability required. Although typically created by metal fabrication, bollards can be created by a number of different manufacturing techniques including metal casting and metal forging.

Fabrication

For steel bollards, the fabrication process typically starts with cutting the steel tubes into specific lengths using saws or other cutting tools. These tubes are then shaped and welded into the desired bollard design, whether it’s a simple cylindrical post or a more intricate, decorative form.

Surface Treatment

Surface treatment is crucial to ensure the bollards withstand environmental elements and retain their appearance. This involves processes like sandblasting to remove impurities, followed by priming and painting to provide corrosion resistance and aesthetic appeal.

For concrete bollards, molds are used to shape the concrete mixtures into the desired forms, often incorporating pigments or aggregates for texture and color. Bollards can also be galvanized or powder coated to ensure durability.

Installation

Once manufactured, bollards are installed by anchoring them firmly into the ground using concrete or specialized mounting systems, ensuring stability and longevity.

Bollard Materials

Bollards, those sturdy posts used for various purposes, are typically made from a range of materials based on their intended function, durability requirements, and aesthetic considerations.

The choice of material for bollards varies based on factors such as location, purpose, and design. Steel, both stainless steel and carbon, remains a popular choice due to its strength and resilience against impact. Concrete bollards provide substantial mass and stability, while aluminum bollards offer lightweight options.

Here are some of the common materials used by The Federal Group for bollard manufacturing:

- Aluminum

- Carbon Steel

- Concrete

- Iron

- Stainless Steel

Bollard Advantages

Bollards offer several advantages that contribute to safety, security, and urban design. Here are some key advantages of using bollards:

- Safety Enhancement: Bollards play a crucial role in improving safety by delineating pedestrian areas from vehicular traffic. They create barriers that guide the flow of vehicles and prevent unauthorized access to restricted zones, reducing the risk of accidents and collisions.

- Security Measures: In high-security areas, such as government buildings, airports, or sensitive installations, bollards act as physical barriers against unauthorized vehicular intrusion. They protect buildings and pedestrians against vehicle-based attacks.

- Traffic Control: Bollards aid in traffic management by controlling vehicle access to specific areas. They can be strategically placed to regulate traffic flow, restrict parking in certain zones, or mark pedestrian walkways, ensuring orderly movement and compliance with traffic regulations.

Conclusion

Bollards, though often inconspicuous, play a vital role in maintaining order, safety, and security in our urban landscapes. Their manufacturing process, whether it involves steel, concrete, or other materials, requires careful planning and precision to create durable structures that withstand the test of time and serve their intended purpose effectively.

Work With a Trusted Bollard Manufacturer

Working with a custom bollard manufacturer offers several advantages, especially when specific requirements, unique designs, or specialized functionalities are needed.

Contact The Federal Group USA today for a free proposal on your next bollard manufacturing project.