Steel is an alloy metal that mainly comprises carbon, iron, and other trace elements in varying concentrations. The difference in compositions gives rise to alloys with unique traits.

One special steel type is carbon steel. Here’s an extensive insight into what carbon steel is, its different variants, special properties, uses, and future trends.

What Makes Carbon Steel Unique?

Carbon steel contains a higher carbon concentration than other steel variants. Other types of steel have a relatively low carbon composition of around 0.05% to 0.3%.

Meanwhile, the carbon content in carbon steel can reach up to 1.25%. While this concentration may sound insubstantial, it provides several excellent properties not present in other metals, such as an appealing strength-to-cost ratio.

Types of Carbon Steel Explained

There are four main carbon steel grades, each with unique features. Understanding the different carbon steel compositions allows you to pick the right carbon steel material for a specific use.

Low-Carbon Steel (Mild Steel): Versatile and Affordable

This carbon steel type contains about 0.05% to 0.25% of carbon. It is one of the most common and largest carbon steel groups. Mild steel is inexpensive, soft, and easy to form. These traits make it an ideal option where high tensile strength isn’t required, such as fencing, pipe manufacturing, cookware making, and construction frame creation.

A notable limitation is that mild steel cannot experience hardening through heat treatment to form martensite. This brittle structure often forms when steel rapidly cools during quenching from a high temperature.

Luckily, there are alternative ways to harden the material, like cold working and adding alloying elements to create high-strength, low-alloy steel. This low-alloy steel contains up to 10% of:

- Copper

- Nickel

- Molybdenum

- Vanadium

Medium-Carbon Steel: Balancing Strength and Ductility

This carbon steel variant contains about 0.25% to 0.60% of carbon and 0.6% to 1.65% of manganese. Adding manganese enhances this steel type’s strength and hardenability.

Subjecting the material to heat treatment further improves its mechanical features. You can also add molybdenum, chromium, and nickel.

Such hardened medium-carbon steels are more sturdy than low-carbon steels at the expense of ductility. This material is preferred in the heavy machinery industry to create parts like shafts, gears, and axles.

High-Carbon Steel: Strength for Specialized Applications

This type of carbon steel comprises about 0.6. to 1.25% of carbon and 0.30 to 0.90% of manganese. Despite having the lowest ductility, it is the toughest of the carbon steels.

The material’s high carbon content makes it very wear-resistant. Some of the specific high-carbon steel types you may find in high-wear resistance scenarios include tool steels and die steels. They contain additional alloying elements that help in the formation of carbide compounds, including:

- Vanadium

- Chromium

- Molybdenum

- Tungsten

Ultra-High-Carbon Steel: Extreme Strength for Demanding Uses

Is carbon steel strong? Well, this variant contains more than 1.25% carbon, imparting an exceptionally high hardness. It is ideal for applications that need excellent durability, such as cutting tools.

Key Properties of Carbon Steel

Carbon steel has versatile characteristics that make it invaluable across multiple industries.

Mechanical Properties: Strength, Ductility, and Hardness

This metal’s mechanical characteristics depend on its carbon content:

- Low-carbon steel is highly ductile, allowing easy weldability.

- Medium carbon steel has a good balance of strength and ductility.

- High-carbon steel is very strong and resistant but relatively harder to shape.

- Ultra-high-carbon steel is the sturdiest as it has the most carbon content.

Effects of Heat Treatment on Carbon Steel

Heat treatment comprises a group of controlled heating and cooling processes that alter a metal’s physical properties. Some of the most common ones include:

- Annealing: This heating process aims to enhance the ease of cutting and forming carbon steel by softening the metal to improve malleability. Annealing involves heating the material to above the upper critical limit temperature. Afterward, you allow it to soak at that temperature for an extended duration and then gradually cool it. This heat treatment process puts the material in its most workable condition, and you can repeat it multiple times when manufacturing a product. The annealing temperature for steel with a high carbon content (above 0.8%) needs to be about 738°C to create a large coarse-grain pearlite structure. Meanwhile, carbon steel with about 0.4% carbon content needs heating above 840°C to produce a workable ferrite and pearlite structure.

- Quenching: This process helps to rapidly cool steel to form martensite, significantly improving its hardness and strength. The cooling process traps the carbon atoms in a less-ordered structure in the steel matrix.

- Tempering: This process relieves some hardness and brittleness from the carbon steel. It essentially balances the toughness and sturdiness to fit the end product’s final use. You start the process by cleaning the workpiece to achieve a bright, gleaming surface. Afterward, you can heat the material below the upper critical point with a blowtorch until an oxide film forms. There’s a carbon steel color tempering guide that helps metalworkers determine when the optimal color is achieved to cool the piece by quenching it in cold water.

These techniques enable the customization of carbon steel for specific uses, from structural beams to precision tools.

Grain Structure and Its Impact on Performance

The grain structure and size of carbon steel particles influence its mechanical behavior. For instance, fine-grained steel offers superior strength and toughness to coarse-grain steel. The fine-grained variant can better resist deformation and cracks.

However, there’s a higher chemical reactivity and energy at the grain boundaries. As a result, a high density of these grains at the boundaries impacts the material’s corrosion resistance performance. Controlling grain size, structure, and boundaries is essential in applications that require resilience, such as pressure vessels and machine frames.

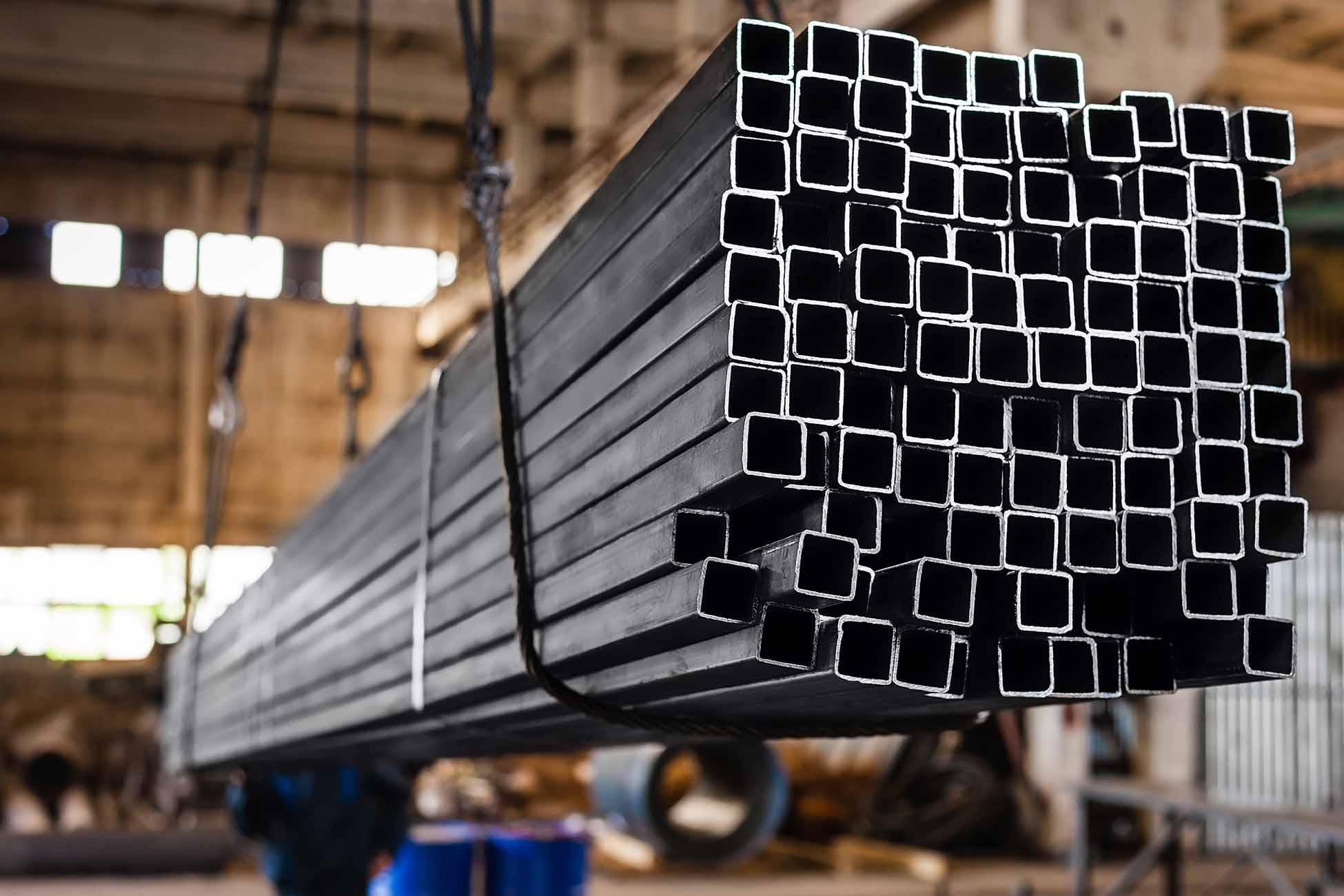

How Carbon Steel Is Used in Manufacturing

You can leverage different manufacturing methods to manipulate carbon steel into durable, precise, and cost-effective components.

Cold-Heading

This metal-forming process allows you to shape carbon steel at room temperature using high pressure. Cold-heading, also known as cold forging, involves the use of dies and hammers at high speeds to remodel the carbon steel workpiece at a low forging temperature.

Low and medium-carbon steels are ideal for cold-heading because of their ductility and ability to withstand deformation without cracking. The process optimizes material usage by reshaping instead of cutting. It also enhances strength through strain or work hardening, making the resulting parts reliable for structural and mechanical uses.

The two main ways of achieving cold heading include:

Cold Heading Upsetting

This entails feeding a large carbon steel wire coil into a drawing machine. The machine then cuts the material into the desired length while compressing it into the desired diameter.

Cold Heading Extrusion

This process can be forward or backward.

- Forward extrusion has two main subtypes. The first one is trapped extrusion which forms parts by compressing the material in a confined space using a punch. It allows the production of precise, intricate shapes like window frames or door profiles. Open extrusion involves deforming the carbon steel slug by forcing it through a die with an open end. It produces components with a consistent cross-section like small rods and pins.

- Backward or reverse extrusion uses the punch to force the metal slug to flow in the opposite direction to the punch movement. This process helps form the large heads and flanges for fasteners like screws, rivets, and bolts.

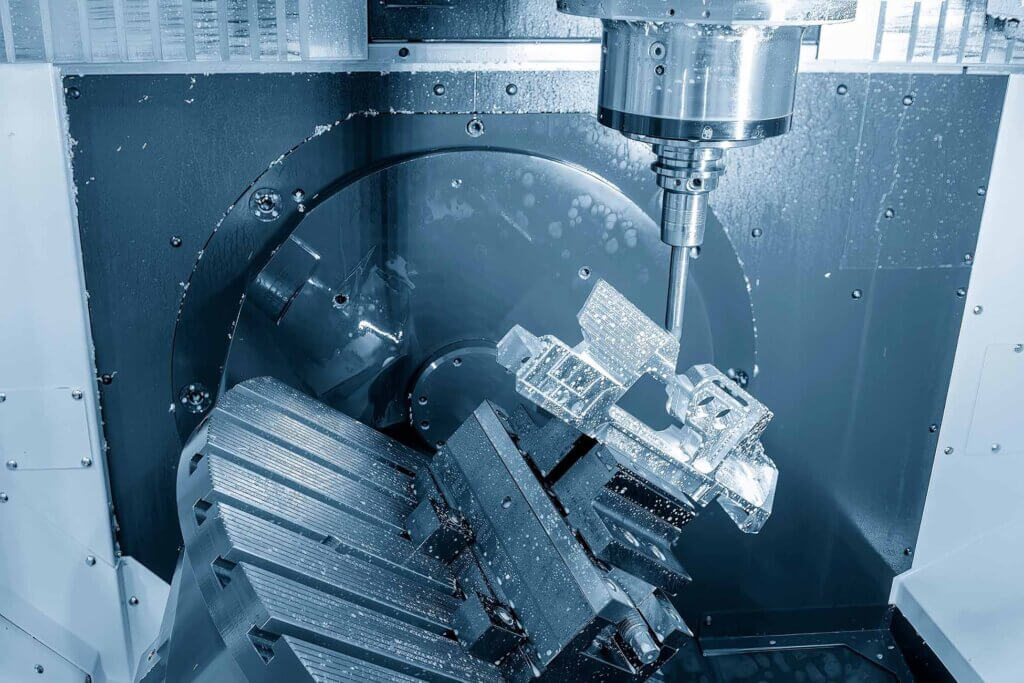

Machining

The machining process involves using different machines to cut and shape the carbon steel workpiece into the final product. The different types of carbon steel precision CNC machining processes available include:

- CNC milling to create contoured or flat shapes and features

- CNC drilling to punch holes into the workpiece

- CNC grinding that uses abrasive wheels to achieve precise tolerances and surface finishes

- CNC lathe to create cylindrical features

Unless heat-treated to wear-resistant or high-tensile levels, carbon steel is generally easy to machine. The carbon steel type with a lower carbon content is more ductile and easier to machine.

Investment Casting

The lost-waxing or investment casting process entails creating precise parts by pouring molten carbon steel into molds formed around wax patterns. Carbon steel for investment casting utilizes a wax pattern with a surrounding ceramic shell to create a ceramic mold.

When this shell dries and hardens, the wax melts away, leaving the formed molds. You can then pour molten carbon steel into the ceramic mold to take up the shape and form a replica of the wax pattern.

Investment casting is ideal for the repeatable low-volume production of parts from low- and medium-carbon steel components.

Benefits and Challenges of Using Carbon Steel

Carbon steel is central to manufacturing due to its numerous advantageous properties. However, like any manufacturing raw material, it comes with its fair share of challenges.

Why Carbon Steel Is the Backbone of Manufacturing

Carbon steel offers the following appealing advantages:

- High and low-temperature resistance

- Corrosion resistance properties

- High durability and strength

- Eco-friendliness

- Low maintenance

- Customizable finishes for better aesthetics

Common Challenges: Corrosion and Welding Issues

Despite all the benefits, some carbon steel types are:

- Difficult to mold and bend into diverse shapes

- Costly to buy

- Easy to dent and damage

- More prone to corrosion and rust

Comparing Carbon Steel to Other Steels

How does carbon steel differ from other steel alloys? Well, when weighing it up against a non-ferrous metal like stainless steel, there are various things to consider to understand the difference between carbon and stainless steel.

- Corrosion Resistance: While carbon steel mainly has iron and carbon constituents, stainless steel also has about 10% chromium. Stainless steel’s large chromium composition helps form an oxide layer that imparts better corrosion resistance than carbon steel.

- Physical Properties: Stainless steel is generally denser than carbon steel and tends to expand more when heated.

- Cost: Stainless steel is more costly than carbon steel due to the presence of nickel and chromium alloy additives.

Future of Carbon Steel: Trends and Innovations

The carbon steel industry has seen transformative shifts due to technological advances, evolving market dynamics, and growing sustainability efforts. Some of the notable carbon steel industry innovations include:

- Industry 4.0 and Digitalization: Advanced techniques like Industry 4.0 are reshaping the carbon steel sector by embracing technology. To enhance efficiency and productivity, smart factories leverage artificial intelligence (AI), Big data analytics, and the Internet of Things (IoT).

- Additive Manufacturing: 3D printing is gaining popularity in the carbon steel industry. This additive process allows the accurate creation of complex parts with minimal wastage.

- Green Steel Production: Research into reducing carbon emissions during steel production is driving the development of sustainable manufacturing processes. These practices include adopting electric arc furnaces, implementing hydrogen-based reduction methods to replace carbon-intensive processes, and integrating carbon capture and storage technologies to trap and store emissions.

Getting Started With Carbon Steel

Carbon steel and steel alloys are essential to making parts across industries, such as construction, machinery, energy, and home appliances sectors. The material’s adaptability and affordability make it a pillar of modern production.

The Federal Group USA experts utilize carbon steel for cold heading and precision CNC machining of different products. Contact us today to learn more about our carbon steel investment casting and how we can support your manufacturing goals.

Holly Cacilhas

Quality Manager

Holly has over 18 years of experience in quality and has worked with brands such as Tesla, BMW, and Chrysler. She has led, trained, and managed teams between 25 and 400 people. Holly enjoys camping, boating, and spending time with her family.

Up Next