Custom Die Casting Company

At The Federal Group USA, we’ve provided custom die casting services for high-quality components since 1980. We offer a wide range of metal capabilities, including aluminum, zinc, and magnesium to manufacture everything from industrial gears and housings to valve bodies and electronic devices.

Request a QuoteDiverse Materials

Aluminum, magnesium, and zinc die casting capabilities.

Secondary Services

CNC machining, heat treatment, coating, plating, and more.

Precision Engineering

Complex die designs optimized for tight tolerances and custom parts.

Advanced Technology

Hot chamber, cold chamber, vacuum, and squeeze die casting processes available.

Die Casting Case Study

A leading manufacturer approached The Federal Group to provide aluminum die casting services for a part that could be used “as cast”—without further machining—while ensuring leak-free assembly.

Diverse Sectors We Serve

The custom die casting solutions offered by The Federal Group USA serve a wide range of industries, from electronics to industrial equipment.

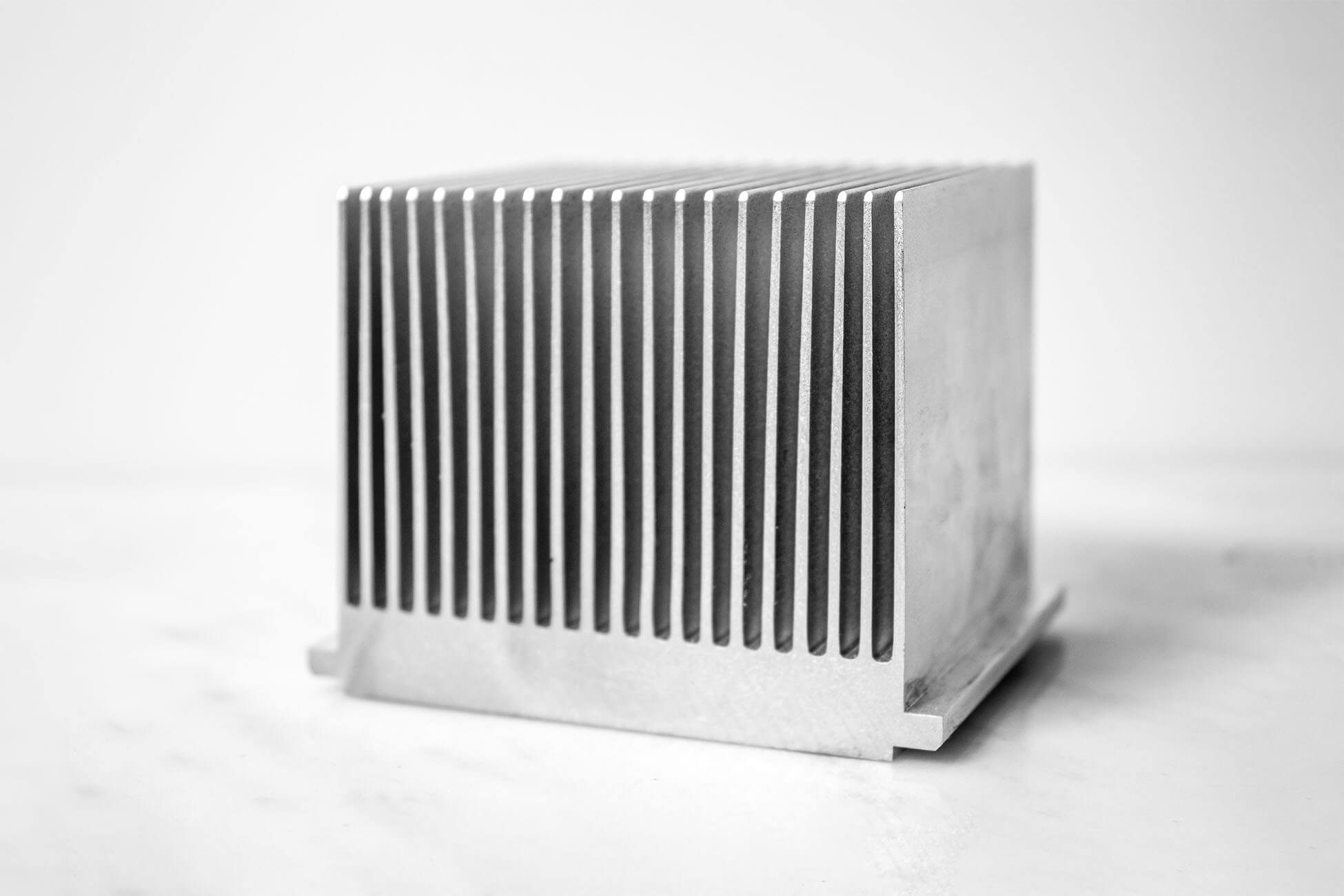

Electronics and Power Systems

Our aluminum and zinc die castings are ideal for housings, heat sinks, and connectors for electrical components. For reliable performance in demanding applications, these lightweight components deliver excellent conductivity and efficient thermal management.

Industrial Equipment and Automation

Die casting from TFG USA provides the robotics, machinery, and automation industries with components that are strong, reliable, and producible at scale. Using lightweight materials, elements such as gear housings and brackets are die cast to maximize cycle efficiency and maintain consistent performance.

Consumer and Commercial Products

TFG’s aluminum and zinc die-cast parts are used in lighting, appliances, and hardware, delivering both durability and aesthetic appeal. With various finish options, including powder coating and anodizing, our parts are supplied with high-quality surface finishes for consumer-facing designs.

Our Die Casting Capabilities and Methods

At The Federal Group, we offer diverse custom die casting manufacturing capabilities, using both high-pressure and gravity die casting with cold-chamber and hot-chamber processes. Hot chamber machines efficiently handle zinc and lower-melting-point alloys, while cold chamber machines are used for aluminum and other higher-melting-point metals. With 600, 800, and 1200-ton machines, our capabilities support fast cycle times for various geometries and sizes.

Tooling is designed for durability, so even with high-volume production, our die casting processes deliver precise results for demanding industrial applications, robotics, and automation systems. We cast everything from electronic housings and manufacturing brackets to industrial equipment and enclosures. Advanced automation and process monitoring systems ensure tight tolerances and repeatable results.

Materials and Alloy Options

Custom die casting manufacturing typically uses non-ferrous alloy materials because it has high dimensional stability. The four most commonly used alloys for die casting are aluminum, magnesium alloys, zinc, and copper.

The choice of die castings materials is influenced by several factors such as density, melting point, strength, resistance to corrosion, and cost. The material also influences the type of machine used.

- Aluminum (A360, A380, ADC12): High strength-to-weight ratio, excellent thermal conductivity, good corrosion resistance, easy to machine. Commonly used for housings, enclosures, and industrial components.

- Magnesium alloys: Very high strength-to-weight ratio, good thermal conductivity, moderate corrosion resistance, lightweight, and suitable for thin-walled parts. Often used in robotics, portable equipment, and complex geometries.

- Zinc: Moderate strength, medium thermal conductivity, fair corrosion resistance, very machineable with a superior surface finish. Ideal for consumer products and intricate components.

- Copper: High strength, excellent thermal conductivity, good corrosion resistance, more challenging to machine with a higher cost. Best for electrical connectors and specialty components.

Finishing and Value-Add Services

As a premier custom die casting company, our die cast components can be delivered ready for assembly, thanks to a full range of finishing and value-added services. Our custom die casting solutions include finishing and secondary CNC machining services, deburring, drilling, threading, and a variety of inspections to ensure material integrity, dimensional accuracy, and consistency.

We also offer a variety of surface finishing options, such as plating, painting, anodizing, and powder coating. With the right finishes, components are more durable, corrosion-resistant, and aesthetically appealing. With our finishing services, die cast components look great and perform reliably.

Quality Control and Risk Mitigation

At The Federal Group USA, quality control is integrated into every stage of our die casting process. Our team uses advanced metrology equipment, CMM inspection, and statistical process control (SPC) to verify precision and consistency.

Upon request, each part undergoes first-article inspection, material certification, PPAP submissions, and final audits to ensure it meets exact specifications. This disciplined approach minimizes risk, reduces defects, and guarantees reliable, repeatable performance for every die-cast component we produce.

Is Die Casting Right for Your Project?

Die casting is ideal for projects that require high-volume casting production and precise dimensions, but it may not be the best fit for every project. The high initial die cast tooling and mold costs mean that this method is best suited for parts produced repeatedly, such as in large production runs, or for parts with complex geometries.

Consider die casting if your project involves:

- High-Volume Production: Die casting is economical when casting hundreds or thousands of parts.

- Tight Tolerances: Ensures precise dimensions and repeatable results.

- Complex Shapes: Supports intricate designs and thin walls.

- Heat Dissipation: Aluminum die castings provide excellent thermal management and durability.

For projects with low volumes, simpler geometries, and less precise tolerances, The Federal Group offers a wide range of metal casting options, including sand casting and investment casting services. Extremely large or heavy parts may also require these alternative casting methods. Metal stamping and forging may be a better fit. With TFG’s custom die casting manufacturing, you can rely on the right solution based on part geometry, size, and mechanical properties.

Start a Die Casting Project Today

Whether your project requires complex shapes, multiple components, high dimensional accuracy, or corrosion resistance, we have the best casting method for you. The Federal Group USA has been a leader in the die casting industry for more than 40 years.

To learn more about our custom die casting processes or to receive a quote for your project, contact us today.