Custom Hot Forging Company

When strength and safety are critical, hot forging is often a preferred manufacturing option. Hot forging has a reputation as a metalworking technique that creates products of uncompromised strength. Find out how hot forging can strengthen your next metalworking project with The Federal Group.

Request a Quote

Trial By Fire

Forging is an ancient technique that’s still plenty relevant in our modern world. In fact, forging continues to produce some of the strongest metals imaginable, so it’s no surprise we’ve seen the market continue to grow.

Forging is an essential metalworking process in the metal manufacturing industry, where it’s used to make everything from the smallest parts and pieces to components weighing hundreds to thousands of pounds.

What is Hot Forging?

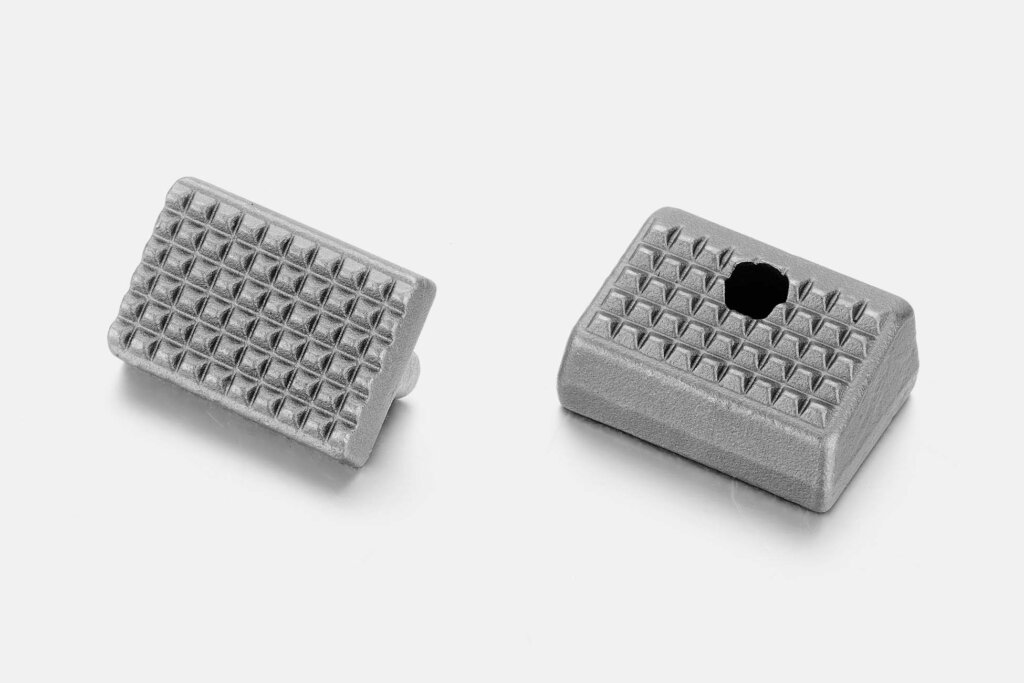

Hot forging, also known as hot forming or drop forging, is a metalworking process that involves shaping and deforming metal at elevated temperatures. Compared to other methods, metal forging produces some of the strongest parts. That’s why working with a custom metal forging manufacturer is key for durable, high-performance components. You’ll often see it used in industries that require strength and durability, such as the marine, construction, and agriculture industries, where it’s used for make structural components for tractors, combines, and plows.

Additionally, forging is commonly used to fortify tools like drill bits used for mining and drilling. For these critical components, forging ensures there are no porosity issues that could cause breakage when drilling deep and through rock.

How Does Hot Forging Work?

Hot forging is a process that entails heating a piece until it’s nearly three-quarters of the way to melting. At this high temperature, metal is more pliable and easier to shape, allowing manufacturers to create more elaborate shapes than with cold forging. However, it’s essential to understand the differences between hot forging vs cold forging, as each method offers unique advantages depending on the material and intended application.

During hot forging, the temperature reaches above the recrystallization point of the metal being formed. The final desired shape is achieved through hammers, presses, or other machinery that compress the heated metal.

How to Find the Best Partner for Hot Forging

Looking for a reliable hot forging manufacturing partner? Your best partner will have engineering acumen in the forging industry, in-house metal forging manufacturing capabilities, speedy turnaround times, and ISO certification in manufacturing. And the longer the manufacturer has been in the forging industry, the better.

We specialize in hot forging with metal materials including:

- Carbon steels, including low-, medium-, and high-carbon steels ideal for high-temperature and high-pressure applications

- Alloy steels, strong, tough, and wear-resistant, commonly used in medical applications

- Stainless steel, a corrosion-resistant option ideal for use in harsh environments

- Aluminum, a lightweight, non-ferrous material commonly used in construction

- Brass, a non-ferrous alloy with antimicrobial properties

- Copper, a non-ferrous and corrosion resistant alloy popular in making instruments for ships

Start a Hot Forging Project Today

The Federal Group has a longstanding reputation of forging excellence with every part and partnership. For forty years, we’ve been known for producing durable and high-quality forgings—and we can’t wait to get to work forging your custom metal parts and components.

Contact us today to get started on a custom project quote.