In this industry, there’s rarely one right way to make a functional part.

That’s where Design for Manufacturing (DFM) comes in. It’s the discipline of matching the proper manufacturing process to the right design—finding the balance that protects quality, trims cost, and makes production repeatable.

At The Federal Group, we know the difference between forging and casting, machining and cold heading, or welding and fastening isn’t just technical—it’s financial, practical, and often what separates a scalable product from a one-off prototype.

And it’s also why our services don’t start or stop at the manufacturing phase.

Table of Contents

The #1 Goal for Design For Manufacturing (DFM) Projects

At its core, DFM is about advancing a design so it can be built effectively and efficiently—without compromising quality or performance.

Or, as clients often put it: “Make it faster, less expensive—and just as reliable.”

Take the aluminum die-cast housing project that we manufactured: the original design carried significant machining requirements that would have driven up both cost and lead time. By re-engineering the approach through die casting services, we reduced unnecessary machining, streamlined production, and improved scalability—all while maintaining performance requirements.

Common goals of DFM include:

- Reducing production costs while protecting quality

- Simplifying complex designs into scalable processes

- Improving manufacturability and repeatability across factories

- Extending product life by aligning the right materials with the right methods

At TFG, we push DFM further. By factoring in supply chain flexibility and leveraging our partner networks, we help clients hit the sweet spot of speed, cost, and quality—not just once, but throughout the entire lifecycle of their product.

Design for (Real) Manufacturing

As we mentioned in the intro, there are “many ways to cut a pie” in manufacturing. Designers may envision one process, but engineers often see alternatives that entirely change the cost, performance, or scalability—without completely changing the part itself.

But process choice is only part of the picture. Great DFM also means anticipating opportunities and challenges, like:

- Packaging, logistics, and supply chain readiness

- Preserving or enhancing part quality and performance

- Adapting existing parts for new applications or environments

We’ve seen this firsthand in a custom metal crimp project. What seemed simple at first had to be adapted for radically different environments—from inland structures to oceanfront installations exposed to constant salt spray. A proactive DFM approach makes these changes practical, effective, and efficient: by selecting the right raw materials and protective metal coatings, we made sure the crimp could perform reliably in various conditions.

And that’s a DFM win—no matter how you slice it.

Designed for Quality

Traditional quality checks are performed after a part is manufactured. But in DFM, quality is engineered into the process from the start. That means:

- Repeatability at scale – building tolerances and inspection requirements into the design phase—often using tools like PFMEA (Process Failure Mode and Effects Analysis) to anticipate risks and prevent defects before production begins.

- Measurement alignment – ensuring everyone (client and factory) uses the same measurement tools (and calibrated tools) and methods to avoid costly mismatches.

- Lifecycle durability – anticipating corrosion, wear, and environmental stresses before tooling is cut.

- Validation and verification – dimensional, functional, and material checks aren’t bolted on at the end; they’re built into every stage of the project lifecycle.

One lesson we’ve learned: quality doesn’t drift when it’s built into the DNA of the design. By pairing DFM with proactive validation, TFG ensures that parts not only pass inspection once but also consistently meet specifications across runs, factories, and real-world conditions.

In DFM—and in life—it’s the intentional, thoughtful details that make the biggest difference.

Designed for Packaging

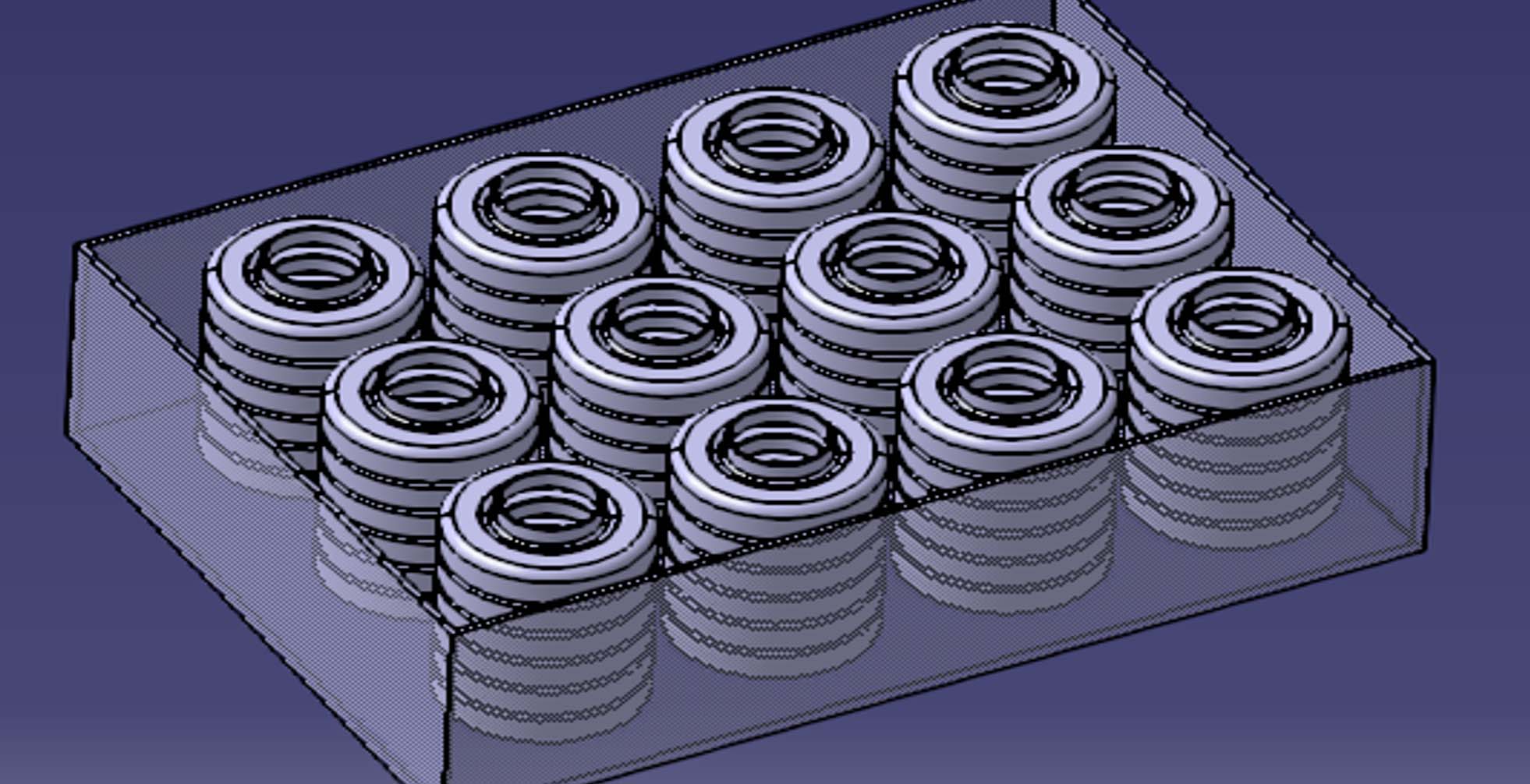

Parts don’t succeed in a vacuum—they succeed when they arrive intact, organized, and ready for use. Packaging isn’t an afterthought; it’s a design variable that impacts stacking, storage, shipping efficiency, damage prevention, and cost.

That’s why we encourage clients to think beyond the CAD file and design with the box, the pallet, and the shipping container in mind.

For projects where packaging plays a critical role, our TFG team can also provide a packaging plan—ensuring the product reaches its destination in the same condition it left the line.

Designed for Logistics & Supply Chain Flexibility

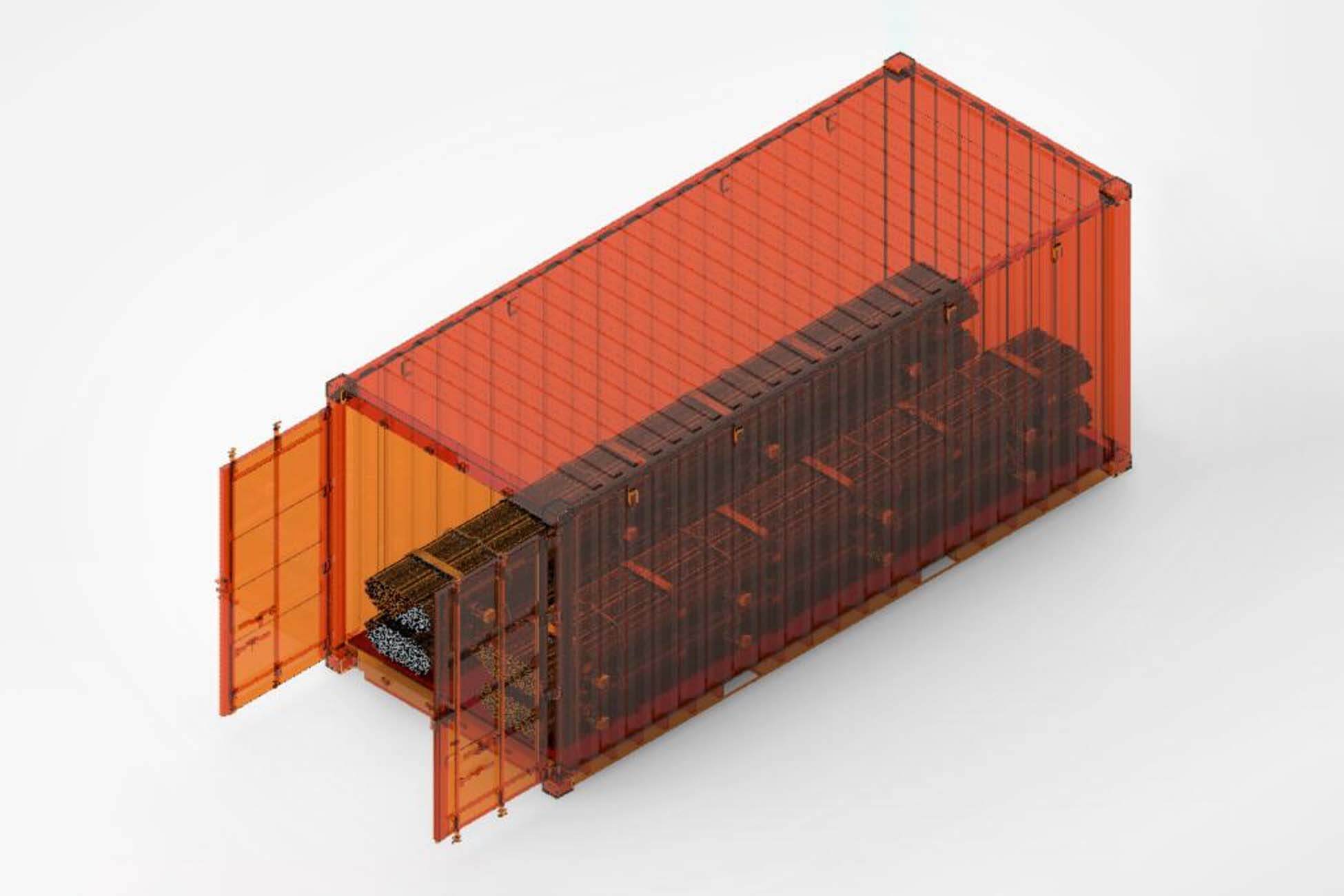

Traditional DFM ends once the parts have been manufactured. But in reality, parts exist inside a global supply chain that can shift overnight—and the best parts are the ones that make it all the way to their destination. That’s why TFG builds logistics and geographical considerations into the DFM process itself.

Smart DFM anticipates:

- Tariff fluctuations – whether listed as separate line items or buffered into cost, with HTS codes factored in up front.

- Alternate or dual sourcing – so production continues even when regions get unstable.

- Freight and lead time variability – designing with shipping modes, customs, and warehousing realities in mind.

- Geographical considerations – the factory’s proximity to the nearest port and the quality of roads and highways (local infrastructure) are all taken into account.

The key isn’t hoping things don’t go wrong—it’s planning for when they do. With a DFM lens on logistics, we always design with a “Plan B” in mind.

By addressing these variables in the design phase—not after the first shipment—TFG ensures projects are not only manufacturable, but also resilient, repeatable, and ready for real-world conditions.

Designed for Partnership

What sets TFG apart isn’t just engineering expertise—it’s perseverance and collaboration. We treat DFM as both a checklist and a partnership—the discipline to catch every detail, paired with the collaboration to keep adapting as the project evolves. That means sticking with a design until it works, even if it takes multiple iterations, factory trials, or testing cycles to get there.

Some projects fail because one side walks away too soon or avoids difficult conversations about when a strategy needs to be adjusted. At TFG, we built persistence into everything we do—and our clients trust we’ll tell them when an adjustment is the smarter path forward.

For us, DFM is more than a design-to-production exercise. It’s a design-to-market strategy. By factoring in packaging, logistics, supply chain realities, and quality from the outset, we help ensure that parts not only meet specifications—they succeed in the real world.

Many companies can make a part. We make sure that part works—for your products, your customers, and your business.

Ready to partner with us? Bring us your napkin sketch—or your most complex CAD file—and let’s make it real. Tell us about your next project here

Mark Cline

Senior Manufacturing Engineer

Mark is an experienced manufacturing leader with a track record of driving operational excellence and product innovation. He previously served as Plant Manager and directed projects as Engineering Manager at established global companies. Throughout his career, Mark has helped launch multi-million dollar products, guiding them from concept to production. His leadership blends deep technical expertise with a strategic mindset, consistently delivering measurable results in complex manufacturing environments.

Up Next