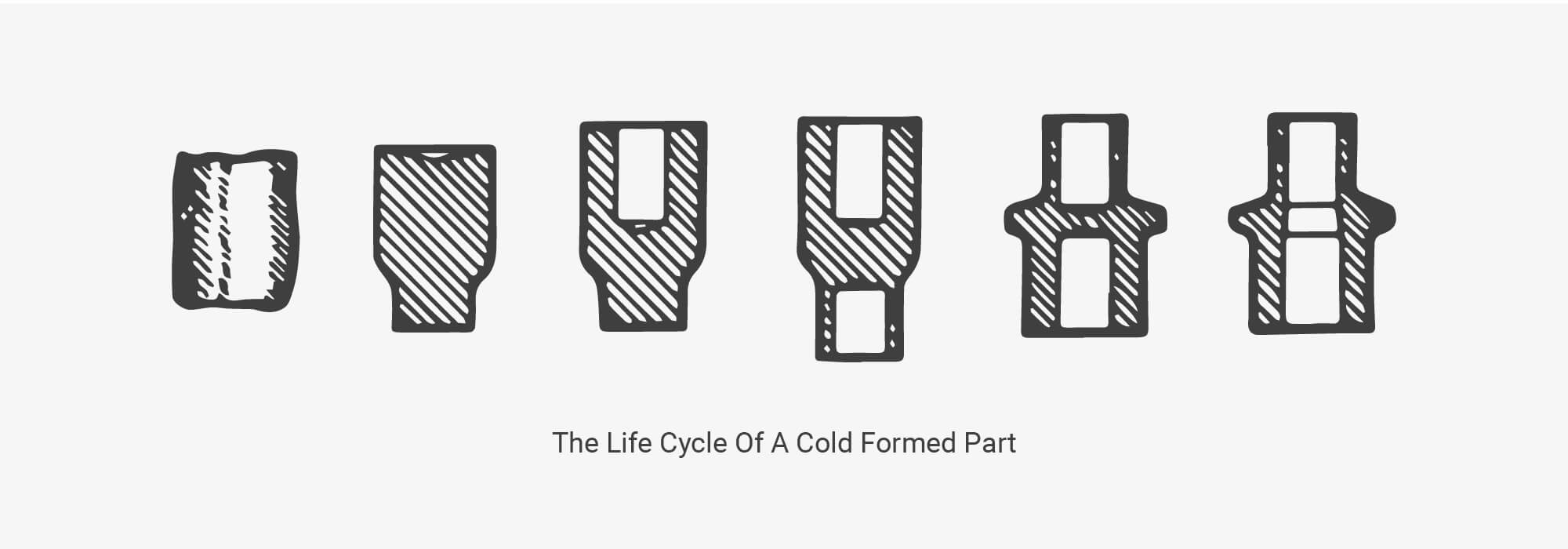

Cold forming, a type of cold working, is an innovative metal forming process that creates metal components with near-net-shape accuracy, low scrap rates, and minimal secondary finishing at cooler temperatures. This technology allows custom fastener manufacturers to produce complex parts like pinions, special screws, rivets, electronic components, and more.

Table of Contents

Key Takeaways

- Efficient Process: Cold forming creates near-net-shape parts with minimal scrap, reduced raw material use, and little need for secondary machining.

- Strength Advantage: Forming at room temperature improves tensile strength compared to hot working methods.

- Versatile techniques: Processes like squeezing, bending, shearing, and drawing produce a wide range of components across industries.

- Cost Savings: Higher production rates, lower material costs, and shorter lead times make cold forming an economical choice.

- Design Considerations: Volume, complexity, strength, and material selection are critical for achieving accurate, cost-effective results.

- Industry Applications: Cold forming is widely used for fasteners, medical devices, bearings, HVAC components, and more.

What Is Cold Forming and Why Is It Important?

Cold forming can produce metal components that are near net shape as they come out of the forming die at an ambient temperature. Unlike hot working, the cooler temperatures provide added tensile strength.

There are many benefits to using this process over traditional manufacturing processes like machining. Some of the advantages include:

- Lower scrap rates

- Reduced raw material usage (with associated cost savings)

- Effective use of existing equipment

- Cold forming reduces downstream processes

What Is the Cold Forming Process?

The four major groups of cold forming are squeezing, bending, shearing, and drawing. Within each of these groups is a multitude of unique techniques that are used to form metal at near room temperature. Keep reading to learn more about the specific processes offered by The Federal Group USA.

- Squeezing: Extrusion, forging, cold rolling, heading, thread rolling, and more.

- Bending: Roll bending, angle bending, and more.

- Shearing: Blanking, piercing, cutting, and more.

- Drawing: Wire drawing, tube drawing, embossing, and more.

Economic Advantages of Cold Forming

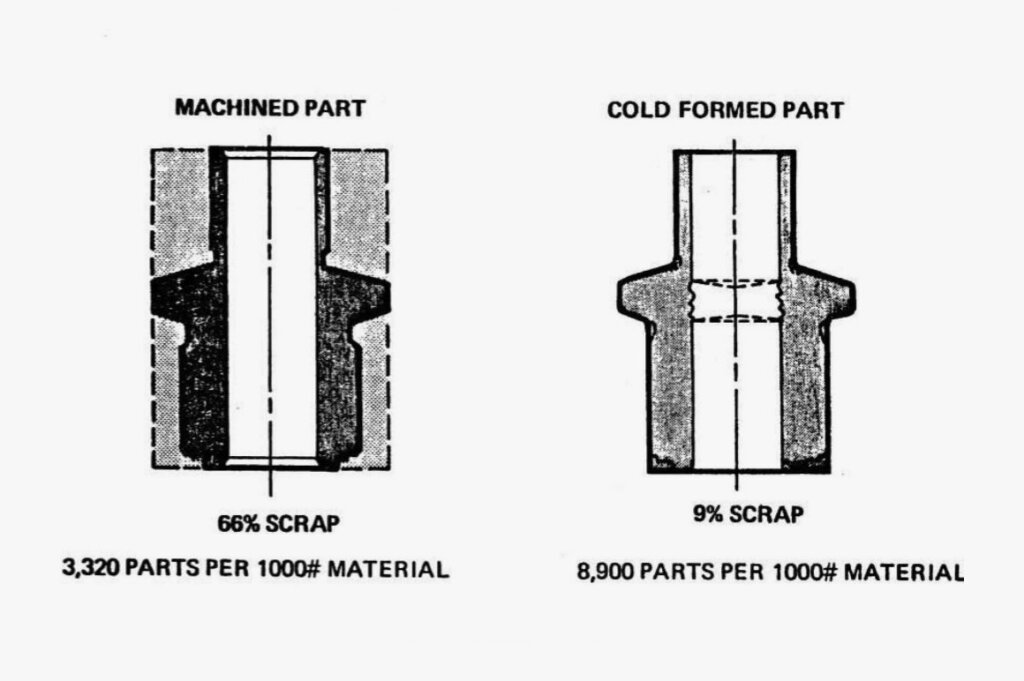

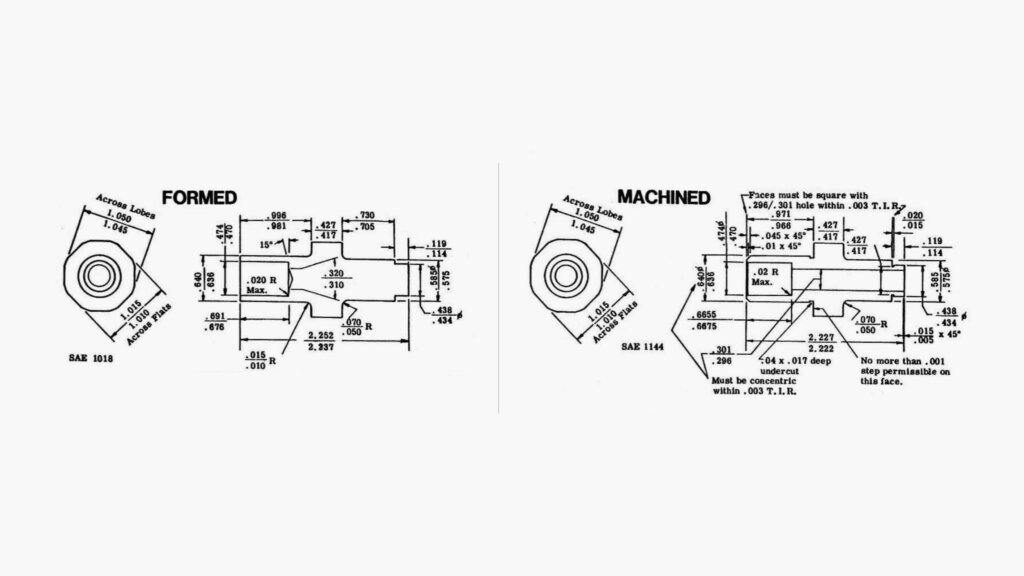

As engineers, we should create and design components to do the job using the most economical capabilities and keep the cost down. Functional analyses examine a part to understand what function it must perform and then develop that element to perform that task.

The design of a component need not be a personal statement about your drawing and engineering abilities. You’ll be the hero if you come up with a part that does the job and is cost-effective to produce. For example, in the illustration above, cold forming will yield over 2x more parts than the same machined part.

The following information should help you create a near net shape cold formed component.

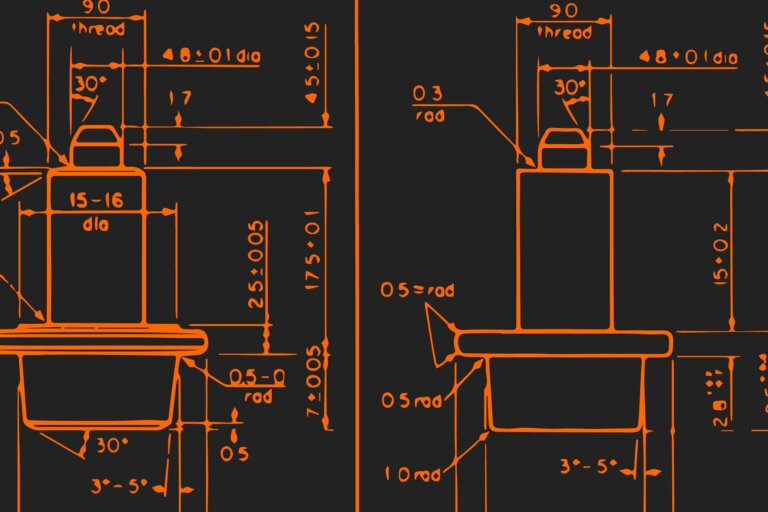

Cold Forming and Dimensional Accuracy

Image above: Plow studs produced by cold forming.

As you design a part for near net shape cold forming (a.k.a. cold working), you must realize that holding tight tolerances is possible. Still, the tighter the tolerance, the more costly it is to manufacture.

What Factors Affect the Dimensional Accuracy of Cold Forming?

Manufacturing conditions govern the accuracy of a cold formed part. The most important factors include:

- Machinery type, process, and condition

- Tooling accuracy

- Raw material quality

- Operator experience

- In-process controls

- Lubricant type

Cold Forming Techniques

Cold forming yields high-quality components. They have a good surface finish and little need for secondary operations to the surface. Below are a few best practices when it comes to the cold forming process.

- Use practical tolerances on all dimensions.

- Avoid sharp corners, undercuts, & chamfers.

- Specify simplified geometry if possible.

- Call out practical concentricity, flatness, & parallelism.

- Define functional surface finish requirements. Heat treating may be required.

- Consider materials optimized for cold forming.

- Understand the mechanical properties specified by the design.

Cold Forming Surface Finish Depends On

- Material state before forming

- Forming process used

- Lubricant employed

- Tooling finish & wear

Near net shapes can be machined or ground to the desired shape to meet a specific need.

With cold heading and forming, the finished part’s accuracy depends on the condition and quality of the machinery, operator, process, and more.

Why Is Cold Forming Used?

Cold forming saves money in a variety of ways:

- Lower material consumption.

- Higher production rates.

- Added strength. Cold formed parts have a higher tensile strength than hot forming metal.

- Consistent quality – because better quality material will perform better to cold forming pressures.

- Does not always require secondary machining operations.

- Shorter lead times.

- Typically less expensive materials needed.

Selecting The Right Part For Cold Forming

Cold forming is a process that uses pressure by forming metal at room temperature into a final product. You should consider the following when designing your cold forming parts:

Volume

Volume is the most crucial consideration when choosing a manufacturing process. Will the volume be enough to support the tooling and development expenses? Our size-to-volume guidelines are intended to keep pricing competitive while offsetting set-up and tooling expenditures.

Complexity

Is the component suitable for cold forming? Seeking assistance from a specialist engineer is essential for creating cold-formed parts, as it involves complex criteria and understanding design parameters. TFG USA has the talented and experienced engineering personnel to collaborate with you throughout the entire process.

Strength

Cold forming generally produces a strong final piece in comparison to metalworking techniques performed at high temperatures, but not all materials have good cold-forming properties. Material selection will depend strongly on the desired shape of the part and the type of secondary operations that will be required. The materials selection guide further down in this article gives a general ranking of the material for cold forming. National Machinery‘s list of materials is considered a reliable source for determining your needs.

Price

In general, cold forming will result in a less expensive component than material removal. Price, however, is determined by the degree of intricacy and quantity.

Common Cold Forming Products

Several types of products can be manufactured using cold forming, including:

- Fasteners: Cold forming is commonly used to produce a wide range of fasteners, such as screws, bolts, nuts, rivets, and other threaded components for the automotive, aerospace industry, and more.

- Bearings: Certain types of bearings, like ball bearings, stainless steel balls, and roller bearings, can be produced using cold forming processes.

- Medical Devices: Some medical devices, like surgical instruments and orthopedic implants, are manufactured using cold forming techniques due to their precision and high strength requirements.

- Hydraulic and Pneumatic Components: Cold-formed parts are commonly used in hydraulic and pneumatic systems, including fittings, couplings, and valves.

- Construction Hardware: Cold forming is used to create construction-related hardware such as nails, screws, anchors, and brackets.

- Energy Industry Components: Components used in the energy sector, including power generation and distribution equipment, can be manufactured through cold forming.

- Plumbing and HVAC Components: Cold forming is used to produce various plumbing and HVAC components like pipe fittings, couplings, and connectors.

The advantages of cold forming, such as improved material properties and dimensional accuracy, make it a preferred choice for producing high-quality components across a wide range of industries.

Cold Forming Operations

Operation | Upsetting Ratio |

One Die | s < 2.3 |

Two Die | s < 4.5 |

Three Die | s < 8.0 |

Multi Die Cold Former* | s < 10.0 |

*Predicated on material and part configuration.

S = Original blank length / original blank diameter.

Cold Formability of Carbon Steels

Best | Good | Fair | Poor |

1008 | 1018 | 1035 | 1045 |

1010 | 1020 | 1038 | 1050 |

1013 | 1022 | 1040 | 1060 |

1016 | 1024 | 1070 | |

1017 | 1030 | 1080 |

The physical and mechanical properties resulting from variable processing of the material selected may influence its rank. Rank of each material may also be influenced by type of cold forming to be done, wire coating, and lubricant.

In Summary

This article is about using cold forming as a method to produce consistent metal production parts. We talk about function, cost, process, and economic advantages.

We also provide guidelines for the cold-forming process and selecting the correct part. Cold forming is a great way to produce metal parts. These are general guidelines for material selection and process optimization.

Work With The Federal Group On Your Next Cold Forming Project

Whether you’re exploring prototyping options for a new metal product, or you have an existing product that you’d like to put into production, The Federal Group USA can help you with your next cold forming project.

We’ve provided high-quality metal fabrication services to a wide variety of industries since 1980. Contact us today to request a quote for your cold forming project.

Richard Jegla

Sales Engineer

Richard has been on The Federal Group team for 24 years and his knowledge spans a variety of mechanical engineering topics. When he isn't assisting his clients, he is routinely working on his motorcycles and off-road vehicle projects.

Up Next