Imagine standing at the edge of innovation, where precision meets durability. That’s where cold chamber die casting shines, especially with metals like aluminum that boast low melting points. This die casting process is a powerhouse for creating parts that are not just strong but also complex in design.

In this deep dive, you’ll learn why the cold chamber die casting process, also known as high pressure die casting, stands out for handling materials such as aluminum. We’re set to uncover how it harnesses injection forces exceeding 10,000 psi and its detailed approach for offsetting shrinkage while solidifying—a key aspect in achieving superior manufacturing standards.

From understanding the core components like shot sleeves and plungers to grasping the ejector pins’ crucial role in mold release, we’re unpacking everything. And by comparing it with its counterpart—the hot chamber die casting method—you’ll see why choosing the right technique matters depending on your metal’s properties.

Table of Contents

Understanding Cold Chamber Die Casting

If you’re wondering why your aluminum die casting project is going the cold chamber route, it’s all about handling those low melting points. Aluminum has a lower melting point, making the cold chamber process a perfect match.

Cold chamber die casting doesn’t mess around when dealing with metals like aluminum. The machine ladles molten metal into a shot sleeve, where a hydraulically operated plunger pushes it into the mold at pressures that can go over 10,000 psi.

Think of it as squeezing toothpaste out of a tube but much hotter and more precise. Employing this technique, we masterfully handle metals that scoff at the mere thought of melting under lesser heat.

Shrinkage compensation isn’t just an afterthought; it’s built right into this high-pressure dance between metal alloy and mold. As the material cools down and starts playing nice by solidifying, we’ve already accounted for any shrinkage it might show.

The Cold Chamber Die Casting Process

In a nutshell, the cold chamber die casting process involves pouring molten metal alloys into a shot sleeve before a hydraulically operated plunger pushes it into the mold cavity. This method is perfect for low melting point alloys that could damage cold chamber die casting machines.

Why does this matter? Because when you’re working with metals such as aluminum or magnesium—known for their strength and lightweight properties—the integrity of your final product depends on minimizing exposure to extreme heat which can alter its characteristics.

Why Choose Aluminum for Cold Chamber Die Casting?

Picking the cold chamber die casting process for aluminum isn’t just throwing darts on a board—it’s because aluminum has some unique charms that make it shine in this setting. With its low melting point, we need something robust enough to handle the heat without flinching—and that’s precisely what this process brings to our manufacturing stage.

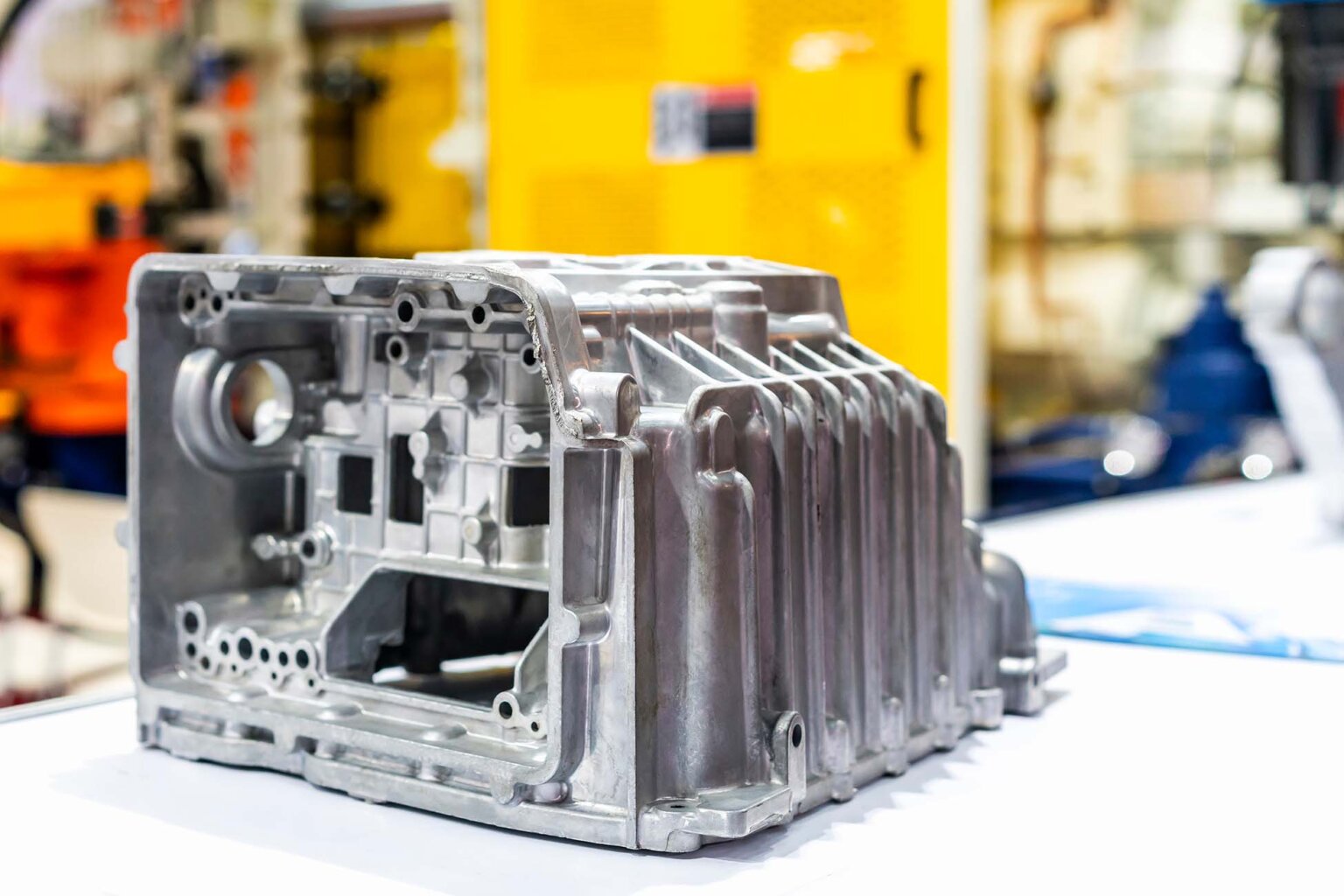

Components of a Cold Chamber Die Casting Machine

The Shot Sleeve and Plunger Mechanism

The heart of the cold chamber die casting machine lies in its shot sleeve and plunger mechanism. The tireless efforts of the shot sleeve and plunger pair, as they meticulously force liquid metal into the mold’s heart.

The separation of the ladle from injector components is more than just an engineering decision; it’s what allows these machines to handle metals with low melting points by minimizing cool down time of the die while decreasing cycle time. For those who appreciate data, think about this: injection pressures can exceed 10,000 psi.

Why does this matter? Well, when dealing with materials like aluminum—which has found its niche in cold chamber processes due to its cantankerous nature at low temperatures—controlling every aspect of the injection ensures not only quality but also repeatability across thousands of parts.

Ejector Pins’ Role in Mold Release

Moving on from brute force to finesse, ejector pins play their part once the casting solidifies. These little heroes ensure that your meticulously crafted component exits the mold without clinging. It’s thanks to these ejector pins that removal is smooth and damage-free—a critical factor given how even minor imperfections can send a part straight to the scrap heap.

The Cold Chamber Die

These dies are CNC machined out of tool steel or carbon steel because they have a melting point of about 2,500 degrees Fahrenheit. This is why any metal with a higher melting point above copper will not be good for die casting.

Advantages of Cold Chamber Die Casting Over The Hot Chamber Method

When it comes to manufacturing with precision and efficiency, choosing the right die casting process is crucial. Cold chamber die casting shines in its application for aluminum and magnesium, offering a distinct advantage over hot chamber die casting due to its usage of metal alloys.

In addition, cold chamber die casting is ideal for parts with tight tolerances and thin walls because the molten metal fills the die at such high pressure and speed which typically creates a part with less porosity. Lastly, cold chamber die casting can produce more parts faster because of the shorter cycle times.

Conclusion

Cold chamber die casting stands as a beacon for precision and strength, especially with low melting point metals like aluminum. And let’s not forget, when faced with tighter tolerances and thinner walls, cold chamber die casting is your go-to method over hot chamber alternatives.

Take your next project from concept to reality with confidence. Contact us today for a free quote.

Richard Jegla

Sales Engineer

Richard has been on The Federal Group team for 24 years and his knowledge spans a variety of mechanical engineering topics. When he isn't assisting his clients, he is routinely working on his motorcycles and off-road vehicle projects.

Up Next